The jaw plate is an important part in the jaw crusher equipment, and its service life directly affects the whole jaw crusher equipment. Therefore, you must consider the hardness and toughness of the jaw plate when you want to choose a correct one.

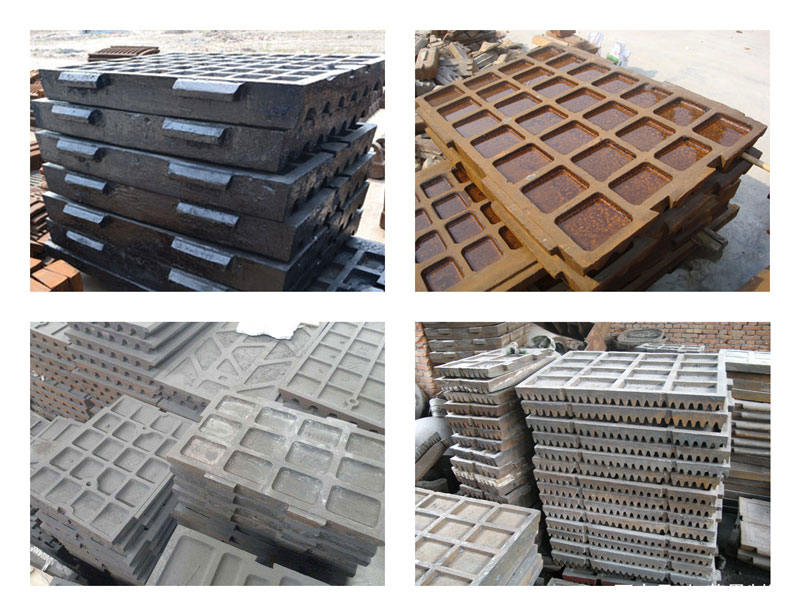

These jaw crusher plates are deliveried to Indonesia

If the hardness of the jaw plate is high, then the depth of the material pressed into the jaw plate will be small, which can prevent the surface from deformation, and reduce the cutting output caused by the sliding of the abrasive.Besides, the jaw plate material must have a certain toughness, which can avoid broken problems during the extrusion process and ensure the normal use of the jaw plates.

There four three main reasons for the wear of the jaw plates:

The material slides for a long time at the discharge port

For double toggle jaw crusher plate, the degree of its vertical swing is greater than that of horizontal swing.

The greater the vertical swing, the longer the ore slides here, so the wear of jaw plate especially the part near the discharge port is more serious.

New jaw plates running in the second-hand jaw crusher

Moreover, the wear of chiseling is greater than that of the extrusion, which makes the lower part of jaw plate wears faster than its the upper part.

In order to increase the its service life, people always turn the lower jaw plate upside down to make both sides pressed uniformly.

Large amount of fines in the material

The wear of jaw plate depends on the types of your material and other variables such as material sizes. Too many fines enter the jaw crusher cavity will accelerate the wear speed of jaw plates because the fines fills the valleys which is necessary for the crusher to crush efficiently.

Generally, a jaw crusher finishes the crushing process by squeezing the material between stationary and moving jaw plates. The peaks and valleys of the jaw plates are offset from one another and use the mechanical advantage of leverage to break the rock.

Without this, the crusher has to rely on energy and friction to crush the rock. The compaction will also impose increased loads on the jaw crusher plates as much as five times the normal crushing force.

over-sized feeding material size

If the feeding material is over-sized, it also seriously affects the service life. In most applications, the reduction ratio of a jaw crusher is 6 to 1. Exceeding the reduction ratio will generate the crushing forces that break the crushers design limits and affect your overall production and machine performance.

For over-sized feed material, if you scrub the material until the jaw plate can get a bite on it, this also accelerates wear.

Using dust suppression with water

Using dust suppression is another factor because the water is actually very abrasive and will accelerate the plates wear.

Fote machinery advises you to use a fine spray dust suppression because it can match water to dust thus reaching the better control of more dust with less water.

That the jaw plate is severely worn can lead to uneven particle size and low efficiency, which indicates that you have to replace the jaw plates. If you want to choose a correct one, you should consider their different materials according to the purpose and real situation.

What kinds of materials are there for jaw plate?

These jaw plates made of high manganese steel

High manganese steel

High manganese steel contains a relatively high carbon content which plays an important role in wear resistance. In general, the hardness increases with the growth of carbon content. Under non-strong impact conditions, increasing the carbon content is beneficial to improve the wear resistance of steel. And this is why high manganese steel has good deformation hardening ability.

Medium manganese steel:

Medium manganese steel has strong hardening ability and stable performance, which creates the function of self-protection when the law plates are subjected to impact and wear. The medium manganese steel jaw plate has achieved good results in the actual production process, and improves service life by 20% compared with that of the high manganese steel jaw plate.

Medium-carbon-low-alloy cast steel:

Medium-carbon-low-alloy cast steel is a widely used wear-resistant material at present. Mainly because of its high hardness and suitable toughness, it can resist fatigue spalling caused by repeated extrusion of materials, and shows good wear resistance.

It can also be adjusted by composition and heat treatment to make the hardness and toughness be changed within a large range. That shows high flexibility strong adaption to the requirements of different working conditions.

Want to buy high-quality jaw crusher plates, click to Get Latest Price

What factors should be considered when choosing the right jaw plate?

Different types of jaw plates

Model and specifications of jaw crushers-What types of jaw plate material you should choose may depend on different specifications, feed size and impact load.

The hardness of the material-The hardness of the material is also an important factor in choosing the jaw plate. The material hardness determines the toughness and strength requirements of the corresponding jaw plate.

Fote machinery manufacturer provides you with the best advice for choosing jaw plate

When to choose high manganese steel jaw plate?

For large jaw crushers, the crushed material is huge-block, which forces the jaw plate to accept strong impact and wear. For that situation, the high manganese steel can give full play to the advantages of good toughness and hardness.

Note: If the flare angle between the moving and fixed jaw plates is too large, it is easy to cause the sliding of the abrasive, deformation and insufficient hardening of the high manganese steel. So sometimes you should adjust the appropriate flare angle during use.

Why it is most suitable to use medium manganese steel jaw plate at this time?

If you need to deal with materials with high hardness such as granite, quartz stone, concrete, etc., the medium manganese steel is the most suitable because of its strong hardening ability. Besides, it has a self-protection mechanism when crushing high hardness materials, which can greatly reduce the wear rate.

When to choose medium-carbon-low-alloy cast steel jaw plates?

Medium and small sized jaw crushers usually bear a low impact load, so under such conditions, medium-carbon-low-alloy steel materials are more suitable. Not only can the disadvantages of high manganese steel difficult to reach the application hardness be avoid, but it also bring good technical and economic benefits.

Where to buy the most suitable jaw crusher plates?

Now that you have clearly understood all the differences between the jaw plates, all that's left is to see which jaw plates are suitable for your jaw crusher, and where you can purchase them.

Fote crusher manufacturer is committed to producing various types of high-quality crushers, and also sell jaw plates and other parts of various materials. You only need to leave some simple information on our website, such as crusher model and specifications, materials, or other requirements, and we will quickly match the jaw plate suitable for your jaw crusher machines.