With the gradual depletion of natural sand, artificial sand becomes the main sand used in building, road construction, etc. So it is very urgent to produce and process artificial sand.

Pebble, which has the advantages of excellent performance, abundant reserves and good mining conditions, has become the main raw material to process artificial sand and received great attention from investors.

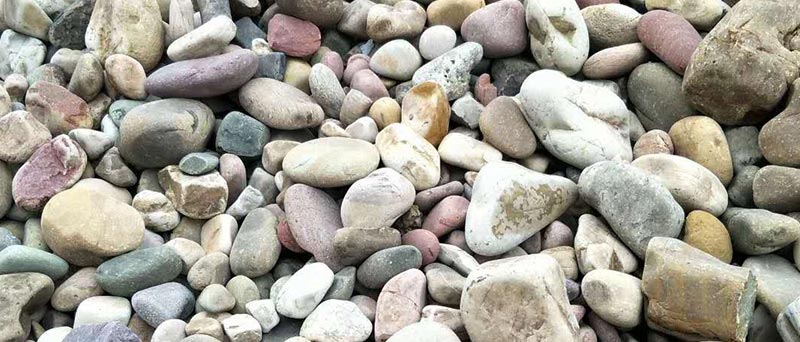

The definition of pebble

Pebble is one of the silicate minerals with the features of hard texture, wear-resistance and steady chemical property. The main component of pebble is silicon dioxide, and its hardness is about 7 when compared to Moh's hardness. The natural pebble stone can be processed to pebble sand through crushing, sand-making, screening and others.

Pebble is the important industrial mineral raw material, which is widely used in the artificial sand production of building fields such as the construction of water conservancy and hydro-power, high way, railway, bridge, airport runway, municipal engineering and high-rise building, etc. Meanwhile, pebble is also used as the concrete aggregate.

The process of making sand by pebble

The whole process of making pebble sand can be divided into five steps: pebble stone → primary crushing (coarse crushing) → secondary crushing → fine crushing (sand plastic) → screening → sand washing → pebble sand.

The first step: Primary crushing

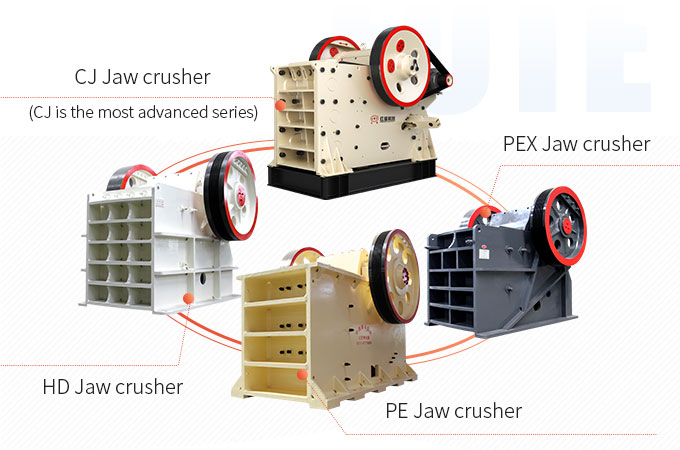

Equipment: Jaw crusher

Jaw crusher is always used in the primary crushing (coarse crushing) process. The jaw machine produced in Fote Heavy Machinery can be used for coarse, medium and fine crushing of various kinds of ores and rocks with compressive strength of 147 to 245 MPa. And this machine has four series currently: PE, PEX, HD and CJ (CJ is the most advanced series).

The feeding size of jaw crusher is between 125 mm to 1200 mm, and its capacity can reach up to 2,200 tons per hour. The jaw crusher crushes the pebble through squeezing, that is, the movable and fixed jaw squeeze each other to break the pebble between them.

The structure of jaw crusher is very simple and its jaw plate is made of high manganese steel which is very wear-resistant, so it costs little in maintenance.

Advantages

- The equipment has a simple structure, and the vulnerable parts are very wear-resistant and can be changed easily, which saves a lot of expense.

- It has a wild range of feeding, large crushing ratio and uniform particle size of finished products.

- It adopts the advanced technology which can improve its efficiency greatly, and single machine energy saving can reach 15% to 30%.

- The equipment is designed according to international environmental standards, and the crusher works with the low crushing noise.

- The machine can be equipped with dust removal, the working site of jaw crusher can fully meet the requirements of environmental protection.

The second step: Medium crushing

Equipment: Toothed roll crusher

To improve the crushing efficiency and reduce the crushing cost, Fote Heavy Machinery has designed the crushing equipment with high efficiency and low energy cost according to the properties of pebble--toothed roll crusher for pebble. This crusher has a cheap price but it is the best for crushing pebbles.

The feeding size of toothed roll crusher is less than 30 mm, and discharging size can reach to 2 mm to 10 mm. The discharging port can be adjusted freely, and the processing capacity can reach up to 110 t/h.

Advantages

- Toothed roll crusher adopts the horizontal structure, which makes feeding and operation easily. The installation and operation of it are easy, and the maintenance is convenient.

- The roll crusher has high crushing efficiency and a large capacity. The finished product has a uniform particle size and low content of needle-like particles.

- The toothed roll crusher has a high degree of automation, strong flexibility and control-ability. The feeding and discharging ports can be adjusted according to customers' requirements. And the range of adjustment is reasonable, which can better satisfy the productive demand of users.

- Toothed roll crusher is made of wear-resistant and pressure-resistant steel, which has high quality and makes the operation more stable. The crusher has a low failure rate and long service life.

- Toothed roll crusher has a high output, which can help improve the production of the whole process line 30% to 40%, and reduce the total energy consumption 20% to 30%.

- During the crushing process, it produces low noise and little dust and can meet the standards of environmental protection and energy-saving.

Note: the model of 2PG700×400 has the best effect in making sand for pebbles.

The third step: Fine crushing (Sand shaping)

Equipment: Pebble sand making machine

Pebble sand making machine is the equipment with high efficiency and environmental protection, whose main function is to eliminate internal cracks in the crushing process of materials and provide high-quality artificial sand for all kinds of building materials.

This sand making machine has a simple structure, reasonable design, stable performance and high efficiency in the working process, providing the market with high-quality sand and stone resources, which is popular among the users. There are various series that can meet the requirements of customers, such as HVI sand maker, VSI sand maker and Vertical Shaft impact crusher.

Advantages

- All the parts are made of excellent steel, which improves the abrasion and service life of machine.

- The sand making machine has a high degree of automation, which helps reduce the labor intensity and save the manual cost and improve the benefit of the factory.

- The sand making machine has flexible adaptability, and there is no dust and noise during operation, which is in line with environmental protection regulations.

- The machine has no requirements on the environment where pebble stones are located, and it can make sand in the harsh environment.

- Compared with the same type of equipment, the energy consumption of this machine is reduced by more than 30%, saving a lot of operating costs for the processing plant.

The fourth step: Screening

Equipment: Vibrating screen

The sieve of the pebble sand generally uses a vibrating screen composed of a sieve box, a vibration exciter, and a motor, etc. The motor is driven by a V-belt to drive the spindle of the exciter to rotate, and the screen box is vibrated due to the centrifugal inertial force of the unbalanced weight on the exciter.

Advantages

- The screen surface inclination angle is 18°, which makes screening efficiency higher.

- The exciter is an eccentric shaft and eccentric block, providing sufficient excitation force.

- The machine adopts the self-lubricating method, and the lubricating oil can be replaced once every 3 to 6 months.

- The key parts are designed with a wear-resistant rubber protective layer to extend the service life of the screen.

The fifth step: Washing sand

Equipment: Sand washing machineIn order to better remove the dirt and impurities in the pebble sand, Fote Heavy Machinery has developed a sand washing machine equipment for the pebble cleaning operation based on the property of the pebble - the pebble sand washing machine, the equipment can be better cleaning the pebble sand to make it easier to use in construction.

- The sand washing machine has a simple structure, and its operation and maintenance are convenient. It is easy to replace the parts, and the maintenance cost is very low, correspondingly reducing the operating cost of the equipment.

- The equipment has a long service life, and all parts are made of very advanced materials, which can make the equipment run more stable, safer and more reliable.

- It can handle a large amount of sand and the cleanliness is very high. It has the characteristics of high efficiency, durability, and good dehydration effect.

- The sand washing machine adapts to a wide working environment and can work under any environment. And there is less wastage of pebble sand, which can meet the demand for materials.

Advantages

Conclusion

After the above links, the pebble is successfully crushed into pebble sand. Due to the increasing technical requirements for sand and gravel in urbanization construction and a large number of key construction projects, the number of natural sand that can meet their requirements has become less or less, or even not.To satisfy the rigid demand of the sand and gravel market, we must find new and better resources to replace natural sand. The artificial sand has become the first choice for construction sand. Therefore, investing in pebble sand making is a good choice, and there is also a bright future.

Since we have our own production plants, technology and sales teams, there are no middlemen who make the profit in prices. The corresponding equipment prices are low and the price set is completely in the range acceptable to consumers.