According to industry statistics, each kilometer of highways and high-speed railways requires hundreds of thousands of tons of sand and gravel aggregates. The quality of some fine sand must meet the standards for construction, otherwise it cannot be sold at a high price. A new-type spiral sand washing machine can solve this problem.

It is a new design result of scientific and technological development, which can improve the grade of sand by one or two levels, allowing customers to obtain multiple economic benefits.

What is the new-type spiral washing machine

The new-type spiral sand washing machine is a kind of sand washing equipment with a horizontal structure. It is an upgraded version of the ordinary sand washer in technological innovation and structure, thereby having the features of outstanding performance, good product size, low unit operating cost, low-carbon and environmental protection.

It is widely used in construction, highway, hydropower plants, sand and gravel plants, concrete mixing plants, etc. It can not only process the coarse-grained materials, but also the medium-grained or fine-grained materials, such as river pebbles, pebbles, granite, basalt, and shale.

After washing, dewatering and separating by the spiral sand washer, the impurities mixed in the sand are removed, and high-quality sand is obtained.

Types and principles

According to the number of internal spirals, the spiral sand washing machine can be divided into two types: single spiral sand washer and double spiral sand washer.

Compared with the single spiral sand washer, the double spiral sand washer has greater output, higher efficiency and can wash the materials with high muddy content.

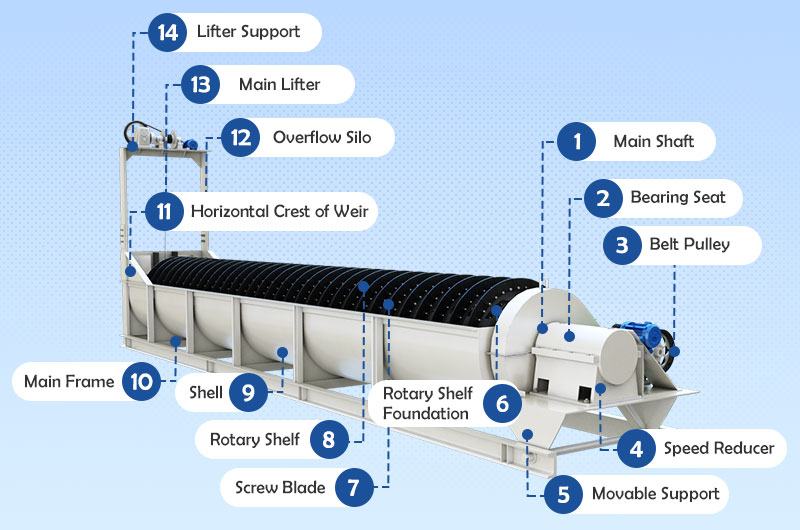

Regardless of single spiral sand washer and double spiral sand washer, the structure is mainly composed of sand washing tank, speed reducer, motor, main shaft, screw blade and lifter support. The structure is simple and has few parts.

The rotor adopts a central structure. The screw blades are installed on the main shaft and connected to the speed reducer to work. The impeller drives the bearing device to make the bearing isolated from water and materials, which can ensure that the finished product is not polluted and effectively improve the cleaning effect.

The spiral sand washer needs to be tilted. Its principle is that the sand and gravel are fed evenly from the feeding tank, and a certain amount of water is continuously injected into the main tank. The transmission part drives the screw shaft to rotate at a certain speed, forcing the materials to mix with water and constantly turning over and colliding with each other.

The impurities (mud, dust, etc.) with low specific gravity are discharged from the overflow silo, while the clean sand is discharged from the discharging port.

In short, the spiral sand washer aims to obtain high-quality sand by mechanical washing according to the spiral principle and the principle of different sedimentation speeds of various materials (sand, mud and water) in the liquid.

Performance advantages

Compared with an ordinary sand washing machine, the spiral sand washing machine has more outstanding advantages and its work efficiency has increased by 50%.

- High degree of cleanliness: The spiral sand washer has a strong cleaning ability. It can effectively clean the sand and gravel with serious mud impurities. Besides, the sand after washing has low water content within 0.8%, which can fully meet the requirements of high-grade materials;

- High efficiency of washing and selection: It has a large processing capacity, high efficiency of washing and selection, and can cause less loss of sand. Thus, it is often configured in the large sand making production lines;

- Low failure rate and long life: It operates stably and almost has no wearing parts. The bearing is isolated from sand and water to avoid premature damage to the machine due to pollution and rust, which greatly reduces the failure rate and extend the life;

- Energy-saving and environmental protection: It has a low power consumption. The cleaned sewage can be recycled through the sedimentation tank, which saves water as well as protects the environment.

Guideline on the spiral sand washing machine

How to install

Before installation, check whether all the parts of the spiral sand washing machine are complete and damaged. After confirming that the machine is intact, it can be installed.

1. First, design the foundation construction drawing of a spiral sand washer according to the specific situation of the site, and install the machine firmly on the solid concrete foundation.

2. When installing, the inclination angle of the machine must meet the requirements of the installation drawing.

3. The motor of the machine shall be installed on the guide rail to adjust the tightness of the belt. The belt pulley and the motor pulley shall be installed in parallel.

4. Finally, rotate the rotor plate several times to check whether it is stuck or collided.

How to test run

Before a spiral sand washing machine is operated, two trial operations must be carried out.

1. No-load Operation

After the motor is started, the sand washer shall operate stably without any abnormal vibration;

- The bearing temperature shall not exceed 35 ℃;

- The sand washer shall be idle for 2-4 hours. Check whether all the connections are loose, and adjust them.

2. Load Operation

- Carry out Load Operation test based on a good result of No-load Operation;

- The machine operates stably without any abnormal vibration;

- The bearing temperature shall not exceed 40 ℃;

- No dust is allowed to enter each sealing place;

- Measure the actual power of the motor without any abnormal fluctuation;

- The Load Operation test shall last for 5-6 hours. After the operation is normal, it can be officially put into production.

How to operate

- Before starting the sand washing machine, check whether there are sundries in the drain hole, and clean it in time to prevent the drain hole from being blocked.

- Carefully check whether all fasteners of the sand washer are fully tightened, especially the new machine.

- Check whether the lubricating oil reaches the height. If not, add the lubricating oil in time.

- Check whether the belt of machine is in good condition. If the belt is damaged, replace it immediately. If the belt is greasy, wipe it with a rag.

- Check whether the protective device is in good condition. If there is any unsafe phenomenon, eliminate it in time.

- After starting the machine, observe whether it is operating normally. If any abnormality is found, stop the machine immediately and check the faults. The machine can only be started again after troubleshooting.

- The sand washer is allowed to start without load.

- During the sand washing, release the flushing water pipe first, then feed the material. At the same time, adjust the spray direction and the height of overflow baffle. The water supply shall be moderate to effectively clean the sand and prevent the sand from overflowing along the notch. When feeding, add sand evenly, not too much or too quickly, as too much sand will cause the overload and damage of machine, and too little will affect the output.

- Do not shut down the machine if there are still many materials inside the machine. And once the machine is shut down, it is not allowed for continuous feeding.

How to maintenance

The bearing is the most easily damaged part, as it often wears a lot in use. Thus, the bearing needs regular maintenance and regular oil filling to increase its life.

- Check the bearing once every two months and pay attention to the reliability of the bearing sealing device. Once severe wear, water seepage, or sand immersion happens, shut down the machine immediately, replace the sealing device, and clean and lubricate the bearing. Generally, the bearing can be oiled every 5000 hours.

- Pay attention to the noise of machine at any time; observe the operation of the screw shaft, V-belt, sealing device, water pipe and other components; check whether the motor and gearbox are overheated and whether the bolts of each part are fastened, etc.

- Clean the gearbox and replace it with oil every 3-6 months. And the bearing pedestal shall be replaced with new grease every 6-12 months.

- The electrical device of large sand equipment must have a reliable grounding device. And the electrical wires shall be reliably insulated and installed in a snakeskin tube. Check the motor wiring frequently for wear and leakage to avoid accidents.

- Seasonal maintenance of sand washer is also very important, mainly to replace the engine oil, fuel oil, antifreeze and add refrigeration equipment.

- Don't touch the machine's body and do some operations like adjusting, cleaning, or repairing when the machine is running.

Common faults and solutions

In production, spiral sand washers often appear with some common faults. The faults include that the sand is not clean; splashing when washing sand; sand washing reduction or leakage; the machine can't start or makes noises; bearing is overheated or damaged; frame vibration; gear damage; noises in transmission part; and blockage of discharging port.

How to solve these faults? Click here for the optimal solutions.