The briquette machine is a device that presses powdery materials into balls. It is easy to burn, smelt, store and transport materials in a spherical shape.

To meet the diverse needs of customers, Ftmmachinery provides you with various types of affordable and suitable briquette machines.

We can process various materials

Ftmmachinery briquette machines can process 4 types of materials:

-

Charcoal powder:

coconut shells, rick husks, bamboo shavings, corn stalks, cotton straws, and other agricultural wastes. Note that we don't process Shisha Charcoal (hookah coals). -

Coal:

coal slurry, coal dust, coal fines, coal powder, fly ash etc. -

Metal ore powder:

iron powder, sponge iron powder, manganese ore fines, aluminum powder, silicon powder, ore tailings, etc. -

Non-metallic ore powder:

asphalt powder, gypsum powder, sludge, kaolin, quicklime/ hydrated lime, fiber powder, fluorspar powder, pet coke fines, etc.

Note:

Carbonization of biomass materials must be done by yourself.

Then we can help you crush and grind them into charcoal powder. Finally, the powder is pressed into charcoal briquettes.

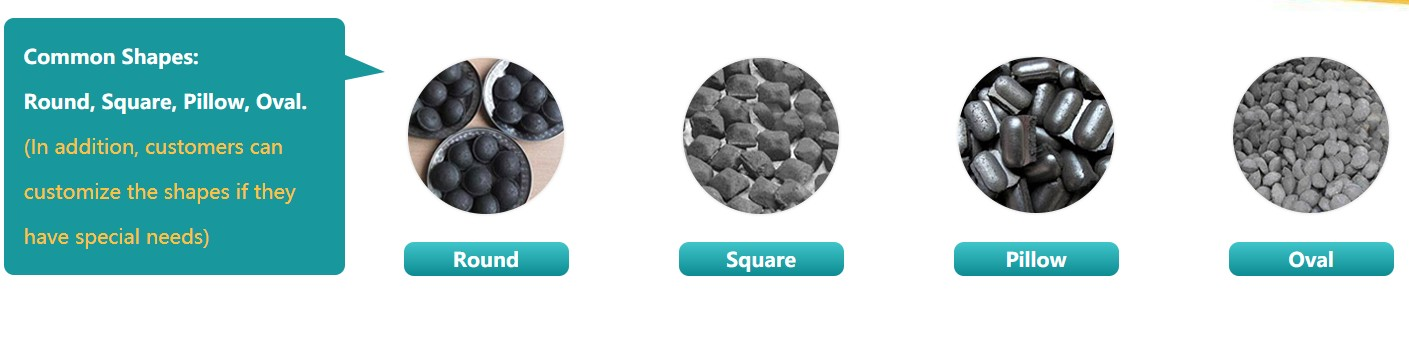

We can press into various shapes

The final shaped balls can be made into round, square, pillow, and oval shapes. In addition, special shapes can be customized according to your needs.

Ftmmachinery briquette machines for sale

Depending on the materials and pellet, we can configure an affordable and efficient briquette machine for you.

The briquette machine is mainly used for pressing powdery materials that are difficult to form. It is characterized by large molding pressure, adjustable rotations of the main engine, and is equipped with a feeding device.

1. Charcoal briquette machine

- Press the powders into high-quality lumps.

- Price: $1, 000/Set (the lowest price)

- Capacity: 2.2-50 t/h

- Materials: Charcoal powder, coal powder, coke powder, mineral powder, gypsum, quicklime, fertilizer, etc.

2. Iron powder briquetting machine

- Produce spherical products with complete shape and high strength.

- Price: $2, 000/Set (the lowest price)

- Capacity: 2.2-50 t/h

- Materials: Suitable for cold-pressed balls of refractory and boiler materials, such as iron ore powder, cast iron powder, manganese ore powder, slag, gypsum, charcoal powder, coal powder, etc.

3. Hydraulic briquetting machine

- Use the hydraulic system to press a variety of powder materials that are difficult to form into balls.

- Price: $1, 000/Set (the lowest price)

- Capacity: 2.2-50 t/h

- Materials: Widely used materials, such as graphite powder, fly ash, oxide slag, iron powder, carbon powder, quicklime powder, magnesium powder, copper powder, chromium powder, aluminum powder, lead-zinc waste, and non-ferrous metal powder.

Selection basis of briquette machine

What factors do you need to consider before choosing a briquette machine?

1. Size: Preferably below 8 mm, preferably a combination of powder and granules.

2. Humidity: Below 12%. It is not easy to form balls if it is too wet or too dry.

3. Shape: Under the premise of the same roller area, the output of the same material and different shapes is quite different.

4. Output: For different output requirements, Ftmmachinery can configure different types of briquette machines for you.

We are your best choice

There are many briquette machine manufacturers in the global market. Why do you choose us?

1. Customization according to material. All equipment and production lines are customized and designed based on the customer's raw materials, avoiding the problems of shape, density, and clogging.

2. Favorable briquette machine price. Integrated molding machine, less cost, high production efficiency, and high yield. It can bring huge economic benefits and value to the plant.

3. Professional and reliable service. With nearly 40 years of experience, Ftmmachinery has designed successful product lines to meet customers' needs for different types of briquette machines.

4. Strong team. Engineer guidance, excellent technology, and a strong after-sales team provide you with the greatest guarantee.

If you have any briquetting requirements for materials, please Contact us, we will provide you with the best solution and reasonable briquette equipment.