What is an impact crusher?

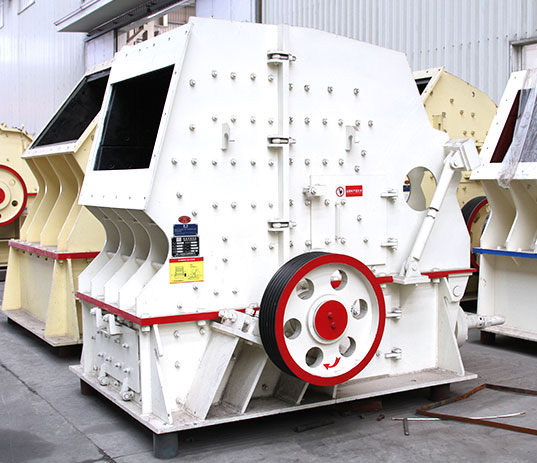

FTM Machinery impact crusher is a processing equipment that uses impact energy to perform secondary and tertiary crushing of medium-hard brittle materials (compressive strength not exceeding 350 MPa).

It is a horizontal shaft impact crusher, often combined with a jaw crusher to form a fixed, portable and track-mounted crushing production line.

The impact rock crushers can crush materials smaller than 800 mm, such as granite, limestone, concrete, etc. Its discharge size is adjustable. The finished product is uniform and cubic, and can be used in mine crushing, railway, highway, energy, cement, chemical, construction and other industries.

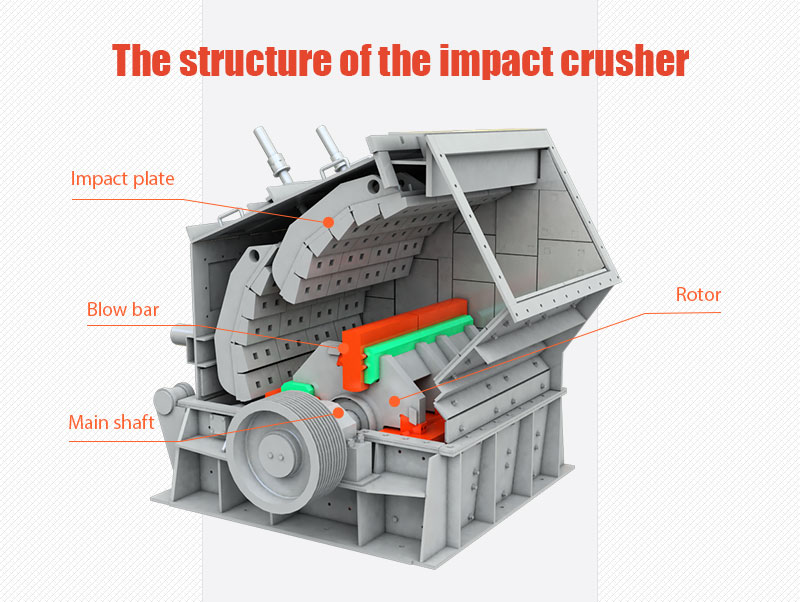

Main parts of the impact crusher

Horizontal impact crusher parts are composed of blow bars, rotor, main shaft and impact plates.

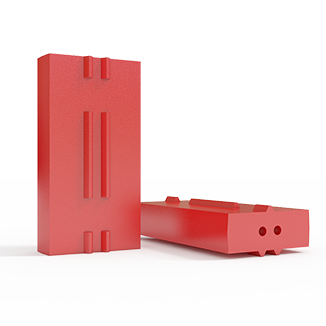

1. Blow bar

The hammer head material is excellent. Each blow bar of the impact crusher is made of high chromium cast iron KmTBCr26, which has good impact resistance and wear resistance, thus prolonging the service life.

The weight of an ordinary blow bar is 160 kg–180 kg, while the weight of the blow bar designed by FTM Machinery is 230 kg, and the crushing efficiency is higher.

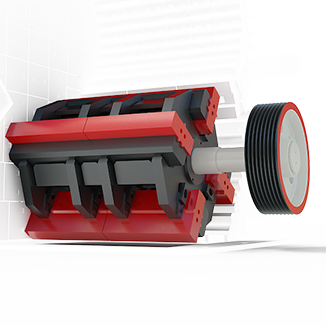

2. Rotor

The rotor is welded by thick steel plate, thick-walled pipe and casting. The main shaft and the rotor are connected by a flat key. The structure is simple, easy to disassemble and assemble.

The efficiency of the rotor designed by FTM Machinery is 80% higher, and it can run smoothly even in the environment of minus 20–30℃, so it is very suitable for high-speed, variable load and impact occasions.

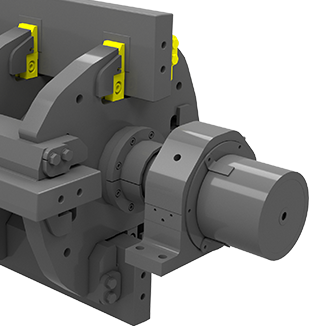

3. Main shaft

The main shaft is the primary component that supports the rotor and carries the impact force.

Therefore, its material is required to have high toughness and strength. Usually the section is circular, and there are flat keys to connect with other parts.

4. Impact plate

There are two impact plates, three-section broken-line impact plate. One can be adjusted, the other is fixed, and the adjusted one depends on the screw device installed on the box.

The impact plate is made of strong wear-resistant materials, the wear resistance has been increased by more than 2 times, the service life is long, and the operation is safer and more stable.

FTM Machinery impact crushers for sale

As one of the world's leading impact crusher manufacturers, FTM Machinery has been committed to innovating crushing technology for more than 40 years.

Currently, it has developed and produced PF Series Impact Crushers, CI Series Impact Crushers, HD German Type Impact Crushers, and Mobile Impact Crushers. If there are special production needs, we also support customized production.

1. PF Series Impact Crusher

It has a large feed port, and a high crushing cavity, suitable for materials with high hardness, large lumps, and less stone powder in the product.

The crusher has a compact structure, and strong machine rigidity. The rotor has a large moment of inertia.

Feed size: ≤800 mm

Capacity: 30–800 t/h

Popular models: PF-1210, PF-1214, and PF-1315

2. CI Series Impact Crusher

It has a compact structure and can be used on mobile crushing equipment. It occupies a small area and has excellent product grain shape. The gap between the impact plate and the blow bar can be adjusted to control the particle size of the finished product.

This is a new type of rock crusher with a large capacity of 2,000 t/h. It has a better crushing effect on materials smaller than 800 mm. The popular models are CI1213 and CI1315.

3. HD German Type Impact Crusher

This crusher is a relatively new crushing model introduced by our company. It sells well, has better performance, and can adapt to a larger output.

The crushing ratio can reach more than 50, so it can be used in single-stage crushing occasions.

Feed size: ≤1,300 mm

Production capacity: 90–670 t/h

Popular models: HD1315 and HD1520

4. Mobile Impact Crusher

There are two kinds of mobile impact crushers: one is the wheeled type and the other is the tracked type. Both of them can be freely configured.

Mobile impact crushers can change the site at any time, which is suitable for customers who require flexible change of site.

The capacity is 40–400 t/h.

Why choose FTM Machinery impact crushers?

- Very high crushing efficiency and large output.

- The product has a good grain shape and is uniform.

- The material of the blow bar as wearing parts is excellent, and the heavy blow bar design is adopted, which is more durable than the high manganese steel material in the market.

- The asymmetrical design of the hopper allows concrete and rocks to hit the hopper first and then pass through the crusher without clogging.

- The hydraulic apron adjustment and overload protection system is capable of monitoring the machine's running status at any time, ensuring it remains operational.

- Low failure rate and low power consumption.

- High-strength frame allows for strong connections and is lightweight for easy maintenance and transportation.

- Hydra arm lift and direct drive system design make machine maintenance more convenient.

- The sealing device design reduces dust and noise, and is more environmentally friendly and safe.

How does an impact crusher work?

When the machine is working, the rotor rotates at a high speed driven by the motor. When the material enters the blow bar action area of the crushing chamber, it collides with the blow bar on the rotor and breaks.

After that, it is thrown to the impact device to be crushed again, and then bounces from the impact liner back to the blow bar action area for re-crushing.

This process is repeated. The material enters the first, second and third impact chambers from large to small for repeated crushing until the material is crushed to the required particle size and discharged from the discharge port.

Customer cases

1. Impact crushers recycling construction waste

Many construction wastes can be reused. If being processed by landfill, it will destroy the environment.

This Australian company is committed to recycling construction waste, and it does successfully get reused sand and aggregate from concrete waste. Last year the company leader Aric contacted us to purchase impact crushing plant. FTM Machinery engineers made a solution for them.

100 TPH stone production line

- Raw materials: Waste concrete and bricks

- Feed size: ≦400 mm

- Motor speed: 2,000 RPM

- Service life of the main wearing parts: about 300 hours (hammers)

- Output size: 0–7 mm, 7–15 mm, 15–20 mm, and 20–40 mm

- Configuration type: Mobile impact crusher

- Estimated investment: USD35,000 to USD63,000

The equipment has been in use for more than a year. According to customer feedback, the impact crusher still runs well, which brings them huge benefits.

2. 180-200 t/h limestone impact crusher in India

- Raw material: Limestone

- Final product: 0–44 mm

- Production demand: 180–120 t/h

- Feed size: ≦1,020 mm

- Configuration type: Jaw crusher+impact crusher+vibrating screen

- Estimated investment: USD46,000–USD103,000

Customer feedback:

"The impact crusher improves 20%–30% more fuel efficient than a standard gear pump, which means the machines have much less hydraulic oil capacity. So, my hydraulic oil reservoirs are about 50%–60% smaller than other machines in this category. Besides, its unique housing design allows me to complete all routine blow bars, rotor, and hammer inspections within 2–3 minutes."

Frequently asked questions about impact crushers

1. What is the difference between impact crushers and jaw crushers?

- a. The feed particle size is different. The impact crusher cannot crush very large materials, so it is used for medium and fine crushing operations. The jaw crusher can directly perform primary crushing on large and hard materials.

- b. The crushing principle is different. Jaw crushers use compressive force to crush material by squeezing it between two plates. Impact crushers use the force of impact to crush material.

- c. The output is different. The impact crusher is finer than the jaw crusher and has better granularity.

2. How do you maintain an impact crusher?

- a. Check oil regularly, making sure it is free of dirt and contaminants.

- b. Check jaw dies every day, and make sure bolts are fastened securely.

- c. Maintain crusher backing to ensure proper vibration and impact protection. Keep breathers clean.

3. Is an impact crusher a primary crusher?

- Impact crushers are generally used as secondary crushers to reduce the finished product of our jaw crushers (primary crushers) to a smaller size. It can crush clay, limestone, coal, dolomite and other medium-hard materials.

- However, if the particle size of the raw material is not too large and the hardness is not high, it can also be used for primary crushing and one-time molding.

Parameter

- PF Series Impact Crusher

- CI Series Impact Crusher

| Model | Specifications (mm) | Feed Opening (mm) | Max.Feeding Size (mm) | Capacity (t/h) | Power (kw) | Dimensions(L×W×H) (mm) |

| PF-1007 | Φ1000×700 | 400×730 | 300 | 30-70 | 4P 37-45 | 2330×1660×2300 |

| PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-90 | 4P 45-55 | 2370×1700×2390 |

| PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 6P 110 | 2680×2160×2800 |

| PF-1214 | Φ1250×1400 | 400×1430 | 350 | 80-180 | 6P 132 | 2650×2460×2800 |

| PF-1315 | Φ1320×1500 | 860×1520 | 500 | 100-280 | 6P 200 | 3180×2720×3120 |

| PF-1320 | Φ1300×2000 | 993×2000 | 500 | 140-380 | 6P 250 | 3220×3100×3120 |

| PF-1520 | Φ1500×2000 | 830×2040 | 700 | 200-550 | 4P 315-400 | 3959×3564×3330 |

| PF-1820 | Φ1800×2000 | 1260×2040 | 800 | 300-800 | 6P 630-710 | 4400×3866×4009 |

| Model | Feed Opening (mm) | Max.Feeding Size (mm) | Capacity (t/h) |

| PF-1007 | 400×730 | 300 | 30-70 |

| PF-1010 | 400×1080 | 350 | 50-90 |

| PF-1210 | 400×1080 | 350 | 70-130 |

| PF-1214 | 400×1430 | 350 | 80-180 |

| PF-1315 | 860×1520 | 500 | 100-280 |

| PF-1320 | 993×20000 | 500 | 140-380 |

| PF-1520 | 830×2040 | 700 | 200-550 |

| PF-1820 | 1260×2040 | 800 | 300-800 |

| Model | Maximum Feeding Size (mm) | Power (kw) | Capacity (t/h) | Dimensions(L×W×H)(mm) |

| CI1110 | 250 | 160 | 60-210 | 2826×2087×2285 |

| CI1213 | 300 | 200 | 80-280 | 2903×2530×2411 |

| CI1316 | 300 | 250 | 100-350 | 3320×2770×2535 |

| CI1521 | 350 | 2×(200-250) | 200-600 | 3450×3620×2770 |

| Model | Maximum Feeding Size (mm) | Power (kw) | Capacity (t/h) | Dimensions(L×W×H)(mm) |

| CI1313 | 600 | 200 | 100-480 | 2972×2560×2937 |

| CI1415 | 600 | 250 | 120-600 | 2985×2790×3068 |

| CI1620 | 800 | 2×(200-250) | 220-900 | 4261×3480×3780 |

| CI2023 | 800 | 2×500 | 400-2000 | 5151×4424×4712 |

| Model | Maximum Feeding Size (mm) | Capacity(t/h) |

| CI1110 | 250 | 60-210 |

| CI1213 | 300 | 80-280 |

| CI1316 | 300 | 100-350 |

| CI1521 | 350 | 200-600 |

| Model | Maximum Feeding Size (mm) | Capacity(t/h) |

| CI1313 | 600 | 100-480 |

| CI1415 | 600 | 120-600 |

| CI1620 | 800 | 220-900 |

| CI2023 | 800 | 200-2000 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.