Wollastonite is a versatile lightweight filler, widely used in ceramics, plastics, and construction. Its carefully processed powder offers a sustainable and efficient grinding alternative to traditional materials like kaolin, mica, and talc.

What is wollastonite?

Wollastonite, a lesser-known yet highly valuable calcium-silicate mineral (CaSiO3), results from impure limestone or dolomite, often with silica-bearing metamorphic rock, exposed to high temperature and pressure.

Wollastonite also appears in regionally metamorphosed rocks in schists, slates, and phyllites.

Wollastonite Properties

- Chemical formula: CaSiO3

- Color: White, colorless or gray

- Luster: Vitreous or dull to pearly on cleavage surfaces

- Streak: White

- Crystal system: Transparent to translucent

- Mohs scale hardness: 4.5 to 5.0

- Specific gravity: 2.86–3.09

- Melting point: 1540°C

- Characteristics: Insulation, high whiteness, excellent dielectric properties, high heat resistance, and good weather resistance.

Wollastonite deposits can be classified into two types:

- Skarn-type Wollastonite Deposits: The ore has a mineral content ranging from 50% to 95%, with small amounts of garnet, diopside, and calcite.

- Marbleization-type Wollastonite Deposits: The ore has a mineral content ranging from 50% to 90%, with main gangue minerals being quartz and calcite.

Where is wollastonite found?

Worldwide, wollastonite resources are abundant but distributed unevenly. The primary concentrations are found in Asia, including China, India, Kazakhstan, Uzbekistan, Tajikistan, and in the Americas, such as Mexico and the United States.

Additionally, countries like Finland, Turkey, Namibia, South Africa, and Yugoslavia have also identified wollastonite deposits.

| Countries and Mines | Ore Types and Main Minerals |

|---|---|

| United States (Willsboro Mine) | Silica skarn type, the ore is mainly composed of wollastonite, garnet, and diopside. Wollastonite accounts for about 55-65%. |

| Finland (Lappeenranta Mine) | Marble type, the ore is mainly composed of wollastonite, calcite, quartz, diopside, and feldspar. Wollastonite content is about 60%. |

| China (Daye Xiaojipu Mine) | Silica skarn type, wollastonite content is 58-62%, with associated minerals including diopside, garnet, calcite, quartz, etc. |

| China (Lishu Dadingshan Mine) | Marble type, the ore is mainly composed of wollastonite, quartz, calcite, diopside. Wollastonite content is about 70-80%. |

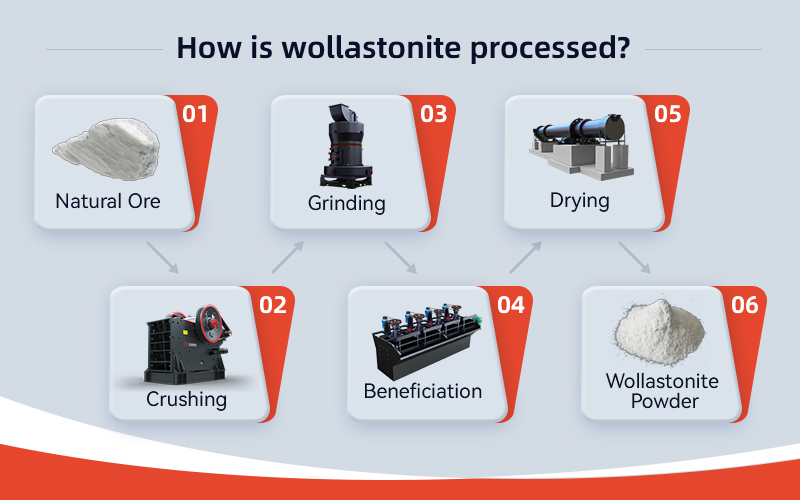

How is wollastonite processed?

To process wollastonite into commercial grades, ore beneficiation is typically conducted to reduce or eliminate undesired associated minerals.

Based on mineral testing, the ore is found to contain wollastonite, calcite, dolomite, garnet, diopside, and silica, with a grade of 73.65%.

FTM Machinery engineers adopted the crushing, grinding, beneficiation, and drying method, achieving a high-quality product meeting market specifications.

Stage 1: Wollastonite Crushing

The mined wollastonite ore undergoes primary crushing to 100-120 millimeters using a jaw crusher, followed by secondary crushing to 30-40 millimeters by a cone crusher.

After crushing, the ore is classified under the action of a vibrating screen, with ore particles that do not meet the size requirements returning to the crusher for further crushing.

Stage 2: Wollastonite Grinding

Generally, the wollastonite plant selects suitable wollastonite milling equipment based on downstream products.

Below are the standards for classifying wollastonite powder by particle size.

| Category | Lump | Regular powder | Fine powder | Ultrafine powder | needle-like powder |

| Particle size | 1 mm-250 mm | <1000 μm | <38 μm | <10 μm | aspect ratio ≥8:1 |

We selected a Raymond mill for grinding based on the ore's characteristics. The blower's airflow transports wollastonite powder to the classifier for grading.

Oversized particles are reintroduced to the grinding chamber for further refinement, and the qualified powder is collected in the cyclone collector through the classifier. Ultimately, we have successfully achieved a grinding fineness of 325 mesh (44 μm).

We have equipped a high-performance pulse dust collector, achieving a remarkable 99% dust removal rate and promoting eco-friendly production.

Wollastonite Raymond Mill

Feeding size: ≤30 mm

Discharging size: 80-325 mesh

Capacity: 8-176 t/shift (8 hours)

Outstanding Advantages of Raymond Mill

- High Screening Efficiency: The screening efficiency of Raymond Mill reaches up to 99%, ensuring uniform fineness of the final powder, surpassing other equipment.

- Adjustable particle size: The fineness of the Raymond mill can be adjusted arbitrarily between 0.173mm and 0.044mm. The achievable upper particle size is 800 mesh.

- Intelligent Control: The electrical system adopts centralized control, enabling the grinding workshop to achieve basic unmanned operation, effectively reducing failure rates and labor costs.

- Low Pollution: The Raymond mill, with excellent sealing performance, creates a work environment characterized by low noise and minimal pollution.

In addition to the Raymond mill, the following equipment can easily handle various powder milling challenges.

| Equipment | Ball mill | Vertical roller mill | HGM ultrafine mill |

| Capacity | 0.65-615 t/h | 2-420 t/h | 0.4-40 t/h |

| Feeding size | ≤25 mm | ≤20 mm | ≤40 mm |

| Discharging size | 20-200 mesh | 20-400 mesh | 60-800 mesh |

We are committed to delivering efficient and reliable powder grinding solutions. For more information or customized inquiries, feel free to contact our team of engineers.Contact us

Stage 3: Wollastonite Beneficiation

After grinding wollastonite, a flotation-magnetic separation combined beneficiation method is employed to remove impurities from the minerals.

Compared to wollastonite, calcite exhibits better floatability. Utilizing sodium silicate as a depressant and industrial oil as a collector in the flotation machine for direct flotation, wollastonite can be effectively separated from gangue minerals (mainly calcite).

Due to the weak magnetic properties of garnet and diopside, a strong magnetic separator is utilized to efficiently separate magnetic substances from wollastonite.

In the end, we achieve a wollastonite concentrate with a grade of 94.31%.

Stage 4: Wollastonite Drying

Due to the moisture content in wollastonite during beneficiation, we use a rotary dryer to eliminate residual moisture by controlling temperature and airflow, ensuring the product achieves the desired dryness.

What is wollastonite powder used for?

The extensive properties of wollastonite make it a versatile material, widely applied in fields such as coatings, plastics, ceramics, and more.

- Coating: Wollastonite powder, replacing some white pigments like titanium dioxide, is a cost-effective extender pigment. Its high gloss, superior waterproofing, and corrosion resistance enhance film thickness and adjust rheological properties.

- Plastics: Due to its outstanding insulation and wear resistance, wollastonite powder improves dimensional stability and fire resistance in plastic components.

- Ceramics: Wollastonite powder contributes to increased firing efficiency, minimizing warping and cracking in ceramics, while enhancing the smoothness of the final products.

- Construction: Resistant to chemical corrosion and inert at high temperatures, wollastonite powder is used as a substitute for asbestos, especially in the manufacture of floor tiles.

- Metallurgy: In the metallurgical industry, wollastonite powder serves as a flux for welding, a source of calcium oxide, and a slag conditioner. It also protects the molten metal surface during the continuous casting of steel.