Which screening equipment is the best? Will you use a vibrating screen or trommel screen (drum screen) for sand and gravel separation?

This article will describe in detail the difference between the trommel screen and vibrating screen as well as the way to choose one benefits you most.

Trommel screen or vibrating screen?

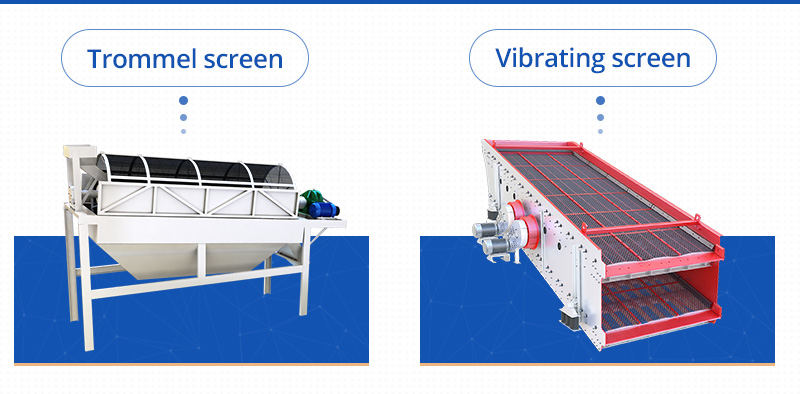

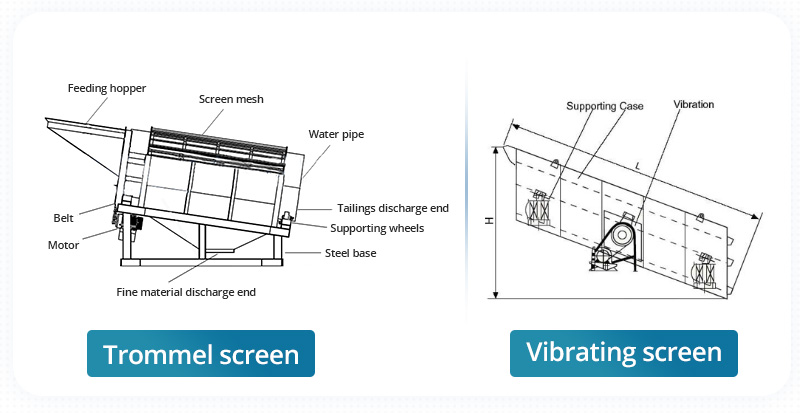

1. Different shapes and structures

Drum screen, with large volume, is a cylinder. It mainly consists of the motor, reducer, drum device, screen, frame, sealing cover, inlet and outlet. The drum device must be equipped with a steel ring to prevent the deformation of the drum screen.

Vibrating screens are divided into circular vibrating screens and linear vibrating screens according to different motion modes.

The vibrating screen is mainly composed of a screen box, a screen frame, a screen, a vibration motor, a motor base, a vibration-damping spring, and a bracket.

The structure of trommel screen and vibrating screen

- Linear vibrating screen: Two vibrating motors are installed at the bottom of the equipment which can be divided into several layers.

- Circular vibrating screen: Also known as single-shaft vibrating screen, its support methods include suspension and seat support.

The trommel screen and vibrating screen are generally composed of the woven screen or punching screen with the hole size of generally 6 mm-8 mm.

2. Different fields of application

Due to the different screening methods of vibrating screen and drum screen, they are good at screening different materials.

The drum screen has a better effect on dust and small particles.

It is widely used in the screening of raw coal, crushed stone and other materials in alumina plants, power plants, coking plants, cement, mining, metallurgy, building materials, coal chemical industries, etc. It is key screening equipment in the coal chemical industry.

Different fields of application of the drum screen and vibrating screen

Linear screens mainly screen fine particles with light specific gravity and low-hardness, mainly dry materials. They are usually used in food, chemical, building materials, and pharmaceutical industries.

The circular vibrating screen mainly screens materials with high specific gravity, large particles and high hardness. It is widely used in mining industries such as mines, coal, and quarries.

3. Different working principles

When the materials are fed into the drum screen, due to its tilt and rotation, qualified materials (undersize product) are discharged through the discharging port at the bottom of the rear end of the drum, while unqualified materials (oversize product) are discharged through the other discharge port.

The screen of the circular vibrating screen is fixed on the screen box. The bearing of the spindle is installed on the screen box, driven by the belt wheel to rotate at high speed.

The linear vibrating screen adopts a vibrating motor as the vibration source, so the material is thrown up on the screen. Then several specifications of undersize products and oversize products are produced through the multi-layer screen. Finally, they are discharged from their respective outlets.

4. Different movement trajectories of materials

- The material on the trommel screen turns and rolls.

- The material on the circular vibrating screen moves in a circular motion.

- The material on the linear screen moves forward in a straight line.

5. Different inclination of the screen surface

The proper angle of inclination enables the material to have proper throwing strength, neither accumulating on the screen surface nor quickly skimming through the screen holes.

Generally, the inclination of the drum screen is 5-30°. It is generally close to 30° for light and fine materials. When the material is heavier, it can be less than 20°, and in special cases, 5-10°.

Different inclination of the screen surface

The inclination of the circular vibrating screen is suitable when it is 20°, and the general range is between 16-20°. If the inclination angle is less than 16°, the material on the screen may not move smoothly or roll upward.

The inclination of the linear vibrating screen is small, between 0-8°.

6. Different materials

- The trommel screen is often made of stainless steel so that the raw materials are not bonded, easy to clean with no sanitary dead angle.

- Thicker plates are used for circular the vibrating screen, and its box body is made of manganese steel to resist the impact of materials during the screening process.

- The materials used for linear vibrating screens are mainly light or stainless-steel plates.

7. Different screening accuracies

The vibrating screen is screening equipment with a vibrating motor as the vibration source, so its screening accuracy is high. The trommel screen is high-output screening equipment with the screening accuracy not as high as the vibrating screen.

8. Different capacities

The feeding size of the trommel screen is small, 50-150 mm. Its production capacity is 500-1500 kg/h, which is suitable for large-scale production requirements in small production lines.

The feeding particle size of the linear vibrating screen is relatively large, ≤ 300 mm. It has small production capacity, 10-600 t/h, so it is suitable for screening fine-sized materials.

Different capacities of two screening equipment

The vibrating screen can screen materials ≤ 400 mm with large capacity (8-800 t/h), which is suitable for medium and large production lines with large output requirements.

9. Different blocking conditions

For the trommel screen, the material is turned over and rolled in the drum, so the material stuck in the screen hole can be ejected to prevent the screen hole from being blocked.

Different blocking conditions when working

As for the circular vibrating screen, the material moves in a parabolic circular trajectory on the screen surface, so the material is dispersed as much as possible to improve the material's bounce force.

The material stuck in its screen hole can also jump out, reducing the phenomenon of blocking.

Conclusion: Vibrating screen or trommel screen?

Different sand and gravel separation equipment have their advantages and disadvantages. It is recommended that you use them reasonably according to different material requirements.

Which one is better? A vibrating screen or a drum screen?

- 1 If it is only for general sand and gravel separation, it is better to choose a vibrating screen. Not only the capacity is guaranteed, but the screening efficiency is also very high.

- 2 When the sand and gravel material you want to separate contains more stone powder, it is more recommended to use a trommel screen. The vibrating screen is not as effective as a drum screen for dust and small materials.

- 3 When you want to separate some sand and gravel materials with high water content, such as coal gangue, etc., it is more reliable to use drum screens to ensure production and prevent the screen holes from being blocked.