Why is a vibrating screen important to the crushing and grinding circuits?

A vibrating screen is a necessary machine for mining and quarrying industries. In the quarrying field, the screening process always follows the primary and secondary crushing stages to divide rock material into more than three sizes from coarse to fine.

Actually, how many sizes of material do you want to get depends on how many screen decks you adding to the machine, which greatly improves the value of raw material. Besides, the vibrating screen also plays a key role in the ore mining industry where ore beneficiation process has strict requirements on the size of ore. For example, before entering a ball grinding mill, ores must get their size meet a ball mill opening size, and be not containing impurities with the help of a vibrating screen.

How does a vibrating screen work?

The working principle of a vibratory screen is quite simple, which makes it easy to operate. The crucial parts of the machine include vibrating screens, exciter, motor, screen decks, liners, and side plates.

Vibrating source comes from an exciter that transmits vibration to the screen deck by the V-belt, which makes material shaking and distributing evenly on the screen. During the process, the large size of material will stay on the top while the small and fine size material can go throughout the screen mesh to the bottom, then you’ll get different sizes of materials.

Vibrating screen parts design

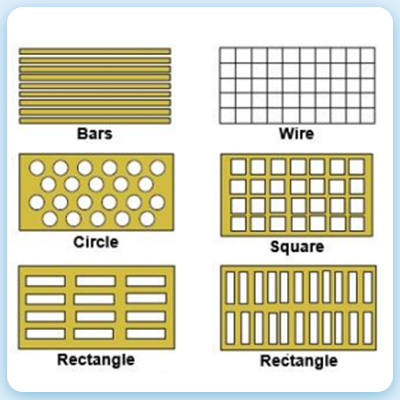

Different types of screen media: The screen (steel wire cloth, nylon wire mesh, bars, a perforated plate with circle, square, rectangle) depends on your product application, granularity, abrasiveness, adhesion, temperature, etc. The picture is from https://practicalmaintenance.net/.

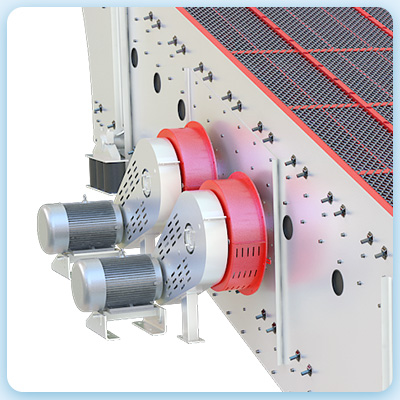

Exciter: The vibration of screen is generated by an exciter that consists of housing, bearing, shaft and an eccentric mass. The screening and frequency can be adjusted by changing the ratio of V-belt sheaves. High-quality exciter can perform a force output of 1000 KN, keeping excellent economic efficiency.

The driven sheave and balance wheels: The driven sheave and balance wheels are the two most important parts being on the centerline of shaft. The task of balance wheel is to ensure centrifugal forces evenly distributing around the axis of rotation, otherwise the unbalanced cause the pulley to vibrate thus leading to premature or even catastrophic failure.

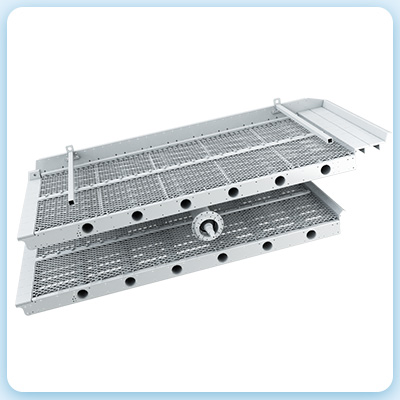

Side plates and liners: Side plates are to resistant vibration and keep the machine body durable and stable. Side plates and liners are assembled by bolts, which not only makes the machine running smoothly but parts replacement, maintenance, cleaning more convenient.

Screen deck: There are single and multiple deck units for floor mounting and suspension. It is easy to add an additional deck or decks on the top or bottom of original deck because the side plates are equipped with flanges containing precision punched bolt holes.

Different types of industrial vibrating screens

1. Inclined vibrating screens/Circular motion vibrating screen

An inclined vibrating screen is one of the most popular screening machines. The inclination of this type of screen is at the range of 15 to 30 degrees. Screening stroke can be adjusted by remove or add eccentric mass and is generally at 8 mm to 12 mm.

The inclined screen utilizes gravity to help material move downward. Besides, the circular motion also helps to separate coarse and fine material. This type of vibrating screen is often applied in stone crushing, sand making, ore processing, construction waste recycling, wet screening, and chemical fields.

2. Horizontal screen

The inclination angle of the horizontal vibrating screen is between 0 degrees and 5 degrees, almost parallel to the ground. It is equipped with a triple drive mechanism that combines advantages of linear and circular vibration types in elliptic vibration.

The triple drive mechanism can keep material moving horizontally under the help of linear vibration while avoid them plunging because of the circular vibration. A horizontal screen has a simple structure, reliable performance, and large capacity, and can overcome any condition. So, it is the most practical vibrating screen in the quarrying field.

3. High-frequency screen

The outstanding feature of a high-frequency screen is high frequency and low amplitude, which ensures a faster material speed thus greatly improving screening efficiency. It is perfect for screening feeds containing solid and crushed ores down to approximately 200μm in size.

It is mostly used in dehydration wet screening in which a filtering layer on the screen surface can block the passage of fine material thus reducing the loss of solid materials in water and improving the recovery rate of solid. It is applied for screening and separating iron ore, tin ore, tungsten, tantalum, and niobium, etc.

Advantages of FTM Machinery vibrating screens

- Steel screen mesh contains carbon making it more durable than a regular screen

- Long service life, safety operation, low cost

- Provide various types of mesh materials and screen shapes

- Available in the online sales and quick ship

- All machines can be custom designs

- Detachable inlet and outlet chutes enable a fast installation and dismantling

- Adjustable counterweights and screening stroke improve screening efficiency

FTM Machinery is one of the leading manufacturers of high-quality vibrating screens. It mainly produces circular motion vibrating screens/inclined vibrating screens, horizontal vibrating screens, high-frequency vibrating screens, drum screens. If you have any needs, please consult our experienced screen engineers to obtain solutions and other information and suggestions.

Vibration screen production cases

1. Vibrating screen for limestone in India

- Model:2YK1225

- Layer: 2

- Material: Limestone

- Production: 55 m³/h

- Price: USD9,000

- Warrancy: 1 year for machinery warrancy

- Product Type: Automatic

- Width: 1,860 mm

- Length: 2,930 mm

- Sieving Precision: 4–50 mm

- Power: 6P 5.5 kW

- Annual Profit:USD70,000

2. Granite screening process in Indonesia

- Model: 3YK1535

- Layer: 3

- Material: Granite

- Production: 120 m³/h

- Price: USD12,000

- Warrancy: 1 year for machinery warrancy

- Product Type: Automatic

- Width: 2,210 mm

- Length: 4,360 mm

- Power: 6P 11 kW

- Annual Profit: USD120,000

3. Linear vibrating screen in South Africa

- Model:4YK1548

- Layer: 4

- Material: Concrete

- Production: 900 m³/h

- Price: USD16,000

- Warrancy: 1 year for machinery warrancy

- Product Type: Automatic

- Width: 2,210 mm

- Length: 6,230 mm

- Sieving Precision: 5-50 mm

- Power: 6P 18.5 kW

- Annual Profit: USD120,000

FAQs about vibrating screens

1. What to do if the vibrating screen bearing becomes abnormally hot or damaged?

- Unreasonable bearing selection: Use special bearings.

- Commonly used vibrating screen bearings generally are cylindrical roller bearings and spherical roller bearings.

2. What is the difference between a circular vibrating screen and a linear vibrating screen?

- The material on the circular vibrating screen moves circularly, and the material on the linear screen moves linearly forward.

3. How to do if the screen frame is broken?

- Sieve frame breakage is generally caused by the seriously shaking of the vibrating screen frame.

- The side panels can be thickened to enhance the rigidity of the entire screen frame.

4. How to deal with clogged of screen mesh?

- The screen mesh of the vibrating screen is blocked mainly because the high mud and water content and make materials stick and block to the screen mesh.

- Solution: First clean the sieve holes, and then adjust the water spray amount and the inclination of the screen surface appropriately.

Parameter

| Model | Sieve layer | Sieve area (㎡) | Mesh size (mm) | Max. feeding size (mm) | Processing capacity (m³/h) | Vibrating Frequency (r/min) | Double amplitude (mm) | Motor power (kw) | Sieve obliquity (°) | Sieve specification (mm) | Dimensions (L×W×H) (mm) |

| 2YK1230 | 2 | 7.2 | 4-50 | 200 | 12-78 | 970 | 6 | 6P 7.5 | 20 | 1200×3000 | 3430×1860×870 |

| 3YK1230 | 3 | 10.8 | 4-50 | 200 | 13-80 | 970 | 6 | 6P 7.5 | 20 | 1200×3000 | 3570×1860×1210 |

| 2YK1237 | 2 | 8.88 | 4-50 | 200 | 15-86 | 970 | 6 | 6P 7.5 | 20 | 1200×3700 | 4050×1860×870 |

| 3YK1237 | 3 | 13.32 | 4-50 | 200 | 16-90 | 970 | 6 | 6P 7.5 | 20 | 1200×3700 | 4270×1860×1210 |

| 2YK1548 | 2 | 14.4 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 11 | 20 | 1500×4800 | 5420×2210×1230 |

| 3YK1548 | 3 | 21.6 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 15 | 20 | 1500×4800 | 5660×2210×1610 |

| 4YK1548 | 4 | 28.8 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 18.5 | 20 | 1500×4800 | 6230×2210×2060 |

| 2YK1854 | 2 | 19.44 | 5-80 | 200 | 32-312 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 5960×2550×1420 |

| 3YK1854 | 3 | 29.16 | 5-80 | 200 | 32-312 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6260×2550×1780 |

| 4YK1854 | 4 | 38.88 | 5-80 | 200 | 32-336 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6830×2550×2160 |

| 2YK2160 | 2 | 25.2 | 5-100 | 200 | 50-475 | 970 | 6 | 6P 30 | 20 | 2100×6000 | 6720×2840×1530 |

| 3YK2160 | 3 | 37.8 | 5-100 | 200 | 50-475 | 970 | 6 | 6P 30 | 20 | 2100×6000 | 7030×2840×1910 |

| 4YK2160 | 4 | 50.4 | 5-100 | 200 | 50-497 | 970 | 6 | 6P 37 | 20 | 2100×6000 | 7300×2840×2380 |

| 2YK2460 | 2 | 28.8 | 5-100 | 200 | 65-550 | 970 | 6 | 6P 30 | 20 | 2400×6000 | 7020×3140×1530 |

| 3YK2460 | 3 | 43.2 | 5-100 | 200 | 70-620 | 970 | 6 | 6P 37 | 20 | 2400×6000 | 7300×3140×1910 |

| 4YK2460 | 4 | 57.6 | 5-100 | 200 | 80-680 | 970 | 6 | 6P 45 | 20 | 2400×6000 | 7600×3140×2380 |

| 2YK2873 | 2 |

39.2 |

5-100 | 200 | 70-680 | 750 | 6 | 6P 37 | 20 | 2800×6440 | 7600×4320×1620 |

| 3YK2873 | 3 | 58.8 | 5-100 | 200 | 80-720 | 750 | 6 | 6P 45 | 20 | 2800×6440 | 7800×4320×2120 |

| 4YK2873 | 4 | 58.8 | 5-100 | 200 | 90-950 | 750 | 6 | 6P 55 | 20 | 2800×6440 | 7800×4320×2120 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Max. feeding size(mm) | Processing capacity(m³/h) |

| 2YK1230 | 200 | 12-78 |

| 3YK1230 | 200 | 13-80 |

| 2YK1237 | 200 | 15-86 |

| 3YK1237 | 200 | 16-90 |

| 2YK1548 | 200 | 22.5-162 |

| 3YK1548 | 200 | 22.5-162 |

| 4YK1548 | 200 | 22.5-162 |

| 2YK1854 | 200 | 32-312 |

| 3YK1854 | 200 | 32-312 |

| 4YK1854 | 200 | 32-336 |

| 2YK2160 | 200 | 50-475 |

| 3YK2160 | 200 | 50-475 |

| 4YK2160 | 200 | 50-497 |

| 2YK2460 | 200 | 65-550 |

| 3YK2460 | 200 | 70-620 |

| 4YK2460 | 200 | 80-680 |

| 2YK2873 | 200 | 70-680 |

| 3YK2873 | 200 | 80-720 |

| 4YK2873 | 200 | 90-950 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.