As manganese ore is low-grade, containing phosphate ore, iron ore and associated metals, it is not easy to separate. Therefore, the efficient and economical separation of manganese ore is crucial.

The manganese ore beneficiation plant aims to produce manganese concentrates of various grades to maximize manganese recovery most economically. Manganese concentrates must meet the requirements of steel and iron industry or other industries.

Manganese ore beneficiation method

Research proves that the most effective manganese ore beneficiation methods are washing, gravity separation, magnetic separation, and flotation separation. (Not include non-mechanical methods like chemical leaching, electrolysis, etc.)

Please note:- Gravity separation had better recover as much manganese as possible, as this method is simple and has a low cost.

- The flotation process of manganese ore can be found here: Flotation process.

- Iron minerals always exist in manganese ores and can be removed by the magnetic separation.

- The recovery of slime is crucial to the recovery of manganese ore.

Different types of manganese ores use different processing processes. Manganese ore is divided into manganese oxide ore, carbonate manganese ore, iron manganese ore, and polymetallic composite manganese ore.

Beneficiation methods of common manganese ores:

| Types | Properties | Beneficiation method |

| Manganese oxide ore (denser) | Simple structure and coarse grains | Gravity separation |

| Manganese oxide ore (leaching type) | Low manganese content, contains slime, and fine grains | Wash and Gravity-magnetic separation |

| Manganese carbonate ore | Fine grains, low phosphorus, and high iron content | Flotation-strong magnetic separation |

| Iron manganese ore | Manganese and iron content is larger than 30% | Wash and Gravity-magnetic separation |

1. Manganese oxide ore beneficiation method

Manganese oxide ore constitutes the majority of available manganese ore. It is mainly dussaurite, pyrolusite, and hydromanganite.

The gangue minerals are silicate and carbonate minerals, accompanied by iron, phosphorus, nickel, cobalt, etc. Manganese oxide ore often produces slime that contains manganese. Therefore, slime is important for recovering manganese.

Manganese oxide ore mainly uses gravity separation.- Massive coarse-grained manganese oxide ore: high manganese content, selected particle size is 40–75mm. It can be simply screened or use gravity separation to obtain rough concentrate by jig or fine concentrate by shaking table.

- Fine-grained leaching-type manganese oxide ore: Low manganese content (within 30%), fine grains, and high slime. This manganese ore needs to be washed by a trommel screen first, then recovered by the combined process of gravity separation (by jig) and strong magnetic separation.

- Very fine-grained leaching-type manganese oxide ore: Low manganese content (less than 15%), fine grains, and uniform inlay. It is difficult to separate, thus we use the chemical leaching method or the combined process of mechanical beneficiation-chemical leaching.

2. Manganese carbonate ore beneficiation method

Manganese carbonate ore is mainly rhodochrosite, calcium rhodochrosite, manganese calcite, and rhodochrosite. Its gangue minerals are silicate and carbonate minerals, often accompanied by impurities like sulfur and iron. It is complex and very fine-grained.

Manganese carbonate ore is processed by the method of flotation - strong magnetic separation.- Sedimentary manganese sulfate-bearing ore: Sequential preferential flotation process of carbonaceous shale, pyrite, and manganese minerals.

- Hydrothermal lead-zinc-carbon-manganese ore: Flotation–strong magnetic separation.

- Sulfur-containing manganese ore: Use the roasting method to remove sulfur.

- High-phosphorus and high-iron fine-grained ore: Very difficult to select. Use chemical leaching method, electrolysis method, etc.

3. Iron manganese ore beneficiation method

Iron manganese ore uses manganese as the main recovered metal. The total content of manganese and iron is more than 30%.

Compared with manganese oxide ore, iron manganese ore is more difficult to select. The difficulty lies in the separation of iron and manganese minerals.

In production, FTM Machinery uses washing - gravity separation - roasting and magnetic separation to recover iron and manganese. The manganese concentrate with 5.4% iron and 46.3% manganese content can be obtained. The recovery rate can reach 75.5%.

Required equipment:4. Polymetallic composite manganese ore beneficiation method

Polymetallic composite manganese ore contains metal minerals, such as iron, lead, zinc, magnesium, aluminum, copper, and silver, mostly in the form of oxide ores. They are closely combined with manganese minerals, making them difficult to separate.

For this manganese ore, we adopt washing and screening, strong magnetic separation, gravity separation, and flotation separation. That is, wash the slime by a trommel screen, and then separate other recyclable minerals.

Required equipment:Slime is essential to manganese recovery. You should find a manufacturer with the overall qualification of the dressing plant for consultation, and select an optimal beneficiation process through scientific mineral testing to ensure the ideal recovery benefits. FTM Machinery can be your good choice! Contact us

Equipment and applications of manganese ore processing plant

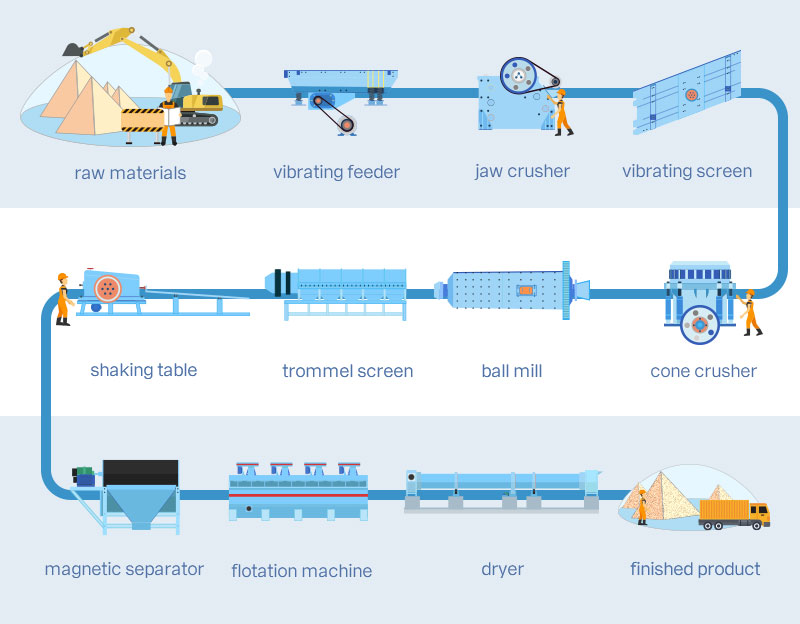

FTM Machinery manganese ore processing equipment includes the vibrating feeder, crusher (jaw crusher, cone crusher), vibrating screen, grinding equipment (ball mill), washing ore equipment (trommel screen), beneficiation equipment (shaking table, flotation machine, magnetic separator), and dryer.

| Equipment | Practical application |

| PE jaw crusher | Crush the manganese ore to below 35 mm for the primary crushing |

| Vibrating screen | Evenly feed the materials (within 1,200 mm) for crushing equipment |

| Cone crusher | Crush the manganese ore to below 15 mm for the secondary crushing |

| Ball mill | Grind the manganese ore into powder of 0.074–0.4 mm |

| Trommel screen | Wash and screen the materials (within 100 mm) |

| 6-S Shaking table | Separate the fine manganese particles |

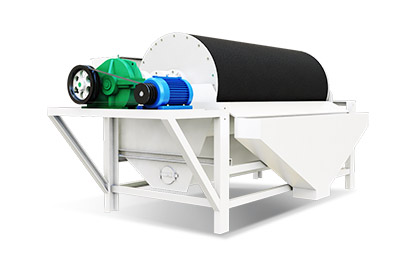

| Magnetic separator | Recycle the manganese concentrate and tailings |

| Flotation machine | Add reagents to separate manganese ore from other substances |

| Rotary drum dryer | After drying, the moisture of manganese concentrate is below 12% or even 0 |

Manganese ore beneficiation plants

1. Nigeria 50TPH manganese ore beneficiation plant

A manganese ore beneficiation plant in Nigeria processes low-grade manganese oxide ore. The manganese (Mn) content is 28%. The productivity is 50 tons per hour. The feeding concentration is 75%.

FTM Machinery recommended solution:Washing, gravity separation (by shaking table), and strong magnetic separation.

- 1Crush the manganese ore to less than 70 mm, and then send it to the trommel screen for washing.

- 2Hand selection for the material larger than 30 mm, and heavy separation by jig for material of 4.5–30 mm.

- 3Use a strong magnetic separator to separate the finest manganese ore within 4.5 mm.

The final result is that the manganese concentrate grade is 41.23% and the recovery rate is 93.6%.

2. Australia 100 TPH manganese ore beneficiation plant

The manganese ore in an Australian manganese processing plant is mainly composed of rhodochrosite and calcium rhodochrosite. Magnetic separation is adopted.

The features of the whole magnetic separation line:- 1The two-stage grinding process is adopted, which can not only reduce the mud ore caused by over-grinding, but also improve the output and achieve the required grinding fineness.

- 2One magnetic separator is used for the first stage of beneficiation. In the second stage, one magnetic separator is used for rough selection and another for ore concentrate.

The final result is that the grade of manganese concentrate is 38% and the recovery rate is 74%.

3. Brazil 200 TPH rock manganese ore beneficiation plant

Brazil's manganese ore plant mainly processes the rock-type manganese ore. The manganese concentrate is about 46% and contains slime. The feed size is 0-400 mm and the output is 200 t/h.

Customer requirements: The product particle size is 20–50 mm. And the manganese concentrate is more than 51%.

Two stage crushing–screening–washing and screening.

| Equipment | Model | Quantity |

| Vibrating feeder | GZD-850×3000 | 1 |

| PE jaw crusher | PE-400×600 | 1 |

| Vibrating screen | 3YK1848 | 2 |

| Belt conveyor | 800*16 m | 8 |

| Cone crusher | PSG 1600 | 1 |

| Trommel screen | YTS1230 | 2 |

4. South Africa 10 TPH manganese ore beneficiation plant

The manganese ore is manganese carbonate ore, which has low manganese content, low phosphorus content, and high iron content.

FTM Machinery recommeneded solution:According to the industrial tests, the grinding process adopts rod grinding-ball grinding, and the equipment scale is φ2100 mm×3000 mm wet-type ball mill. The beneficiation method is strong magnetic-flotation separation. The flotation machine type is JJF.

The final result is that the strong magnetic - flotation separation process was successfully tested and applied in production.

Why choose FTM Machinery?

FTM Machinery is a professional manganese ore equipment manufacturer with nearly 40 years of experience in plant construction and beneficiation technology. We can help you customize the manganese ore beneficiation plant.

- Complete beneficiation solution that suits you. We provide professional guidance and technical support.

- Low investment, high return. Our machines for sale are cheap in price but reliable in quality. We are popular among the users. The plant has a large capacity and high efficiency.

- High degree of automation, reducing the cost of labor and time.

- Low maintenance cost. We increase the machines' service life by more than three times and reduce the maintenance frequency.

- Environmentally friendly plant. It is low in energy consumption and dust emission.