Potash is the term that describes potassium-containing salts used as agricultural fertilizers. Most potash is derived from potassium chloride (KCl). As a source of soluble potassium, potash is vital to agriculture as a primary plant nutrient.

Most potash fertilizers are made from potash ore. This blog will introduce the process of potash ore to make potash fertilizer.

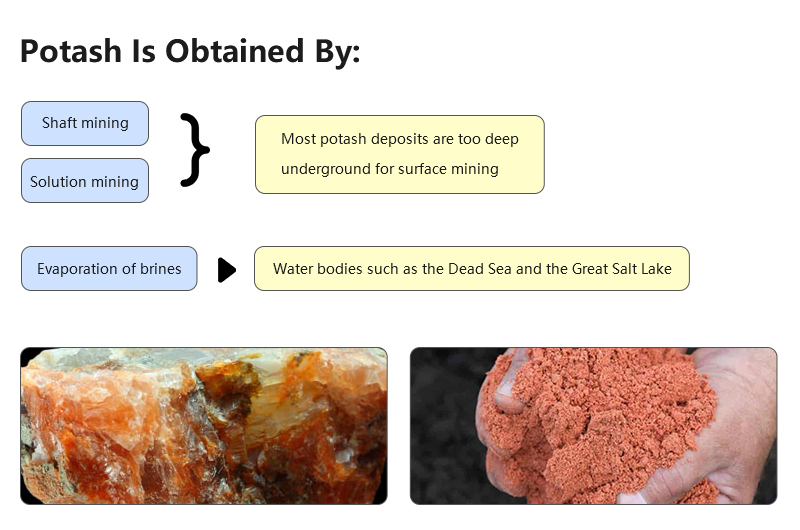

Potassium mining

Deeply buried potash deposits exist throughout the world, particularly in Canada (Saskatchewan), Russia (Ural region) and southern Belarus. The main mineral is sylvite (potash salt) mixed with halite (sodium chloride).

Today, the potash rock comes from either underground or solution mining.

Most potash is recovered through underground Shaft Mining. Concentrated potash is sold as a granular fertilizer with various particle sizes and colors (red and white).

Solution mining is carried out when deposits are deeper than 1,100 meters. This means that hot water is injected into the ground to dissolve the soluble potash salt) and then pump the brine to the surface, where the water evaporates. Besides, solar evaporation is used to recover valuable potash salts from brine water in the Dead Sea and the Great Salt Lake.

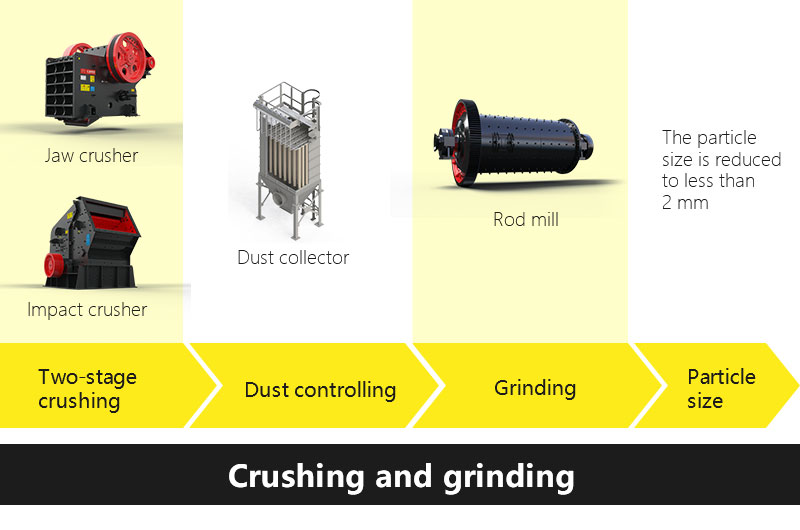

Crushing and grinding

Two-stage crushing. Use a jaw crusher and impact crusher to reduce the particle size to less than 2 mm. It can release the potash and salt crystals and agitation to separate the crystals from the clay particles.

Then, use a vibrating screen to remove clay particles.

Due to the soft and only slightly abrasive character of the salts, the crushing process must be dust controlled by a dust collector.

If finer grinding is required, the ore can be fed into an open circuit rod mill.

Washing and desliming

For many European countries, washing and desliming are important because potash rock has considerable clay slime, which makes it difficult to separate the slime from the brine circuits.

The potash rock is rinsed with saturated brine and a trommel screen is used to remove clay and impurities.

Flotation separation

The potash rock generally contains 20% to 40% KCI, with the remainder being NaCl and a small amount of clay slime. It is coarsely crystalline and free from sodium salts at about 10 to 14 mesh.

Flotation separation is the main separation process for potassium salts, and positive flotation is used.

- The density of the solution in the flotation machine is between 1.99 and 2.16 g/cm3.

- Add the reagents such as starch or Guartec to neutralize and inhibit any slime that forms.

- Add a frothing agent such as pine oil to control froth.

- Amine reagents allow potash to attach to air bubbles and float KCl to the surface, while NaCl and clay sink to the bottom and are discarded as tailings. In addition, the amine-coated particles are less likely to clump or agglomerate when dried.

- Anionic flotation is carried out using naphthenic acid and metal salts (e.g. lead chloride) to float the sodium chloride from the potash.

- The flotation machine will effectively produce high-grade concentrates. With complete desliming in the classification, the grade will remain at 61 to 62% K2O and the concentrate recovery will be approximately 95%.

Dewatering and drying

The wet potash concentrate is detwatered and then sent to a rotary drum dryer to dry at 200°C.

Screening and sizing

A vibrating screen is used to separate the dried ore into various particle sizes to create standard, granular, and suspension-grade potash fertilizers.

Finer products can be further crushed by adding a roll crusher.

Fertilizer granulating

The potash fertilizers with better shapes can be manufactured using a disc granulator. The dried concentrate can be pressed into granular materials.

The dried concentrate can be pressed into a granular form of potash.

Know more about fertilizer granulating.

Conclusion

Ftmmachinery provides process consultation and flowsheet design for your potash deposits to maximize grade and recovery. Our product line includes crushing equipment, grinding equipment, flotation plant, drying equipment, etc. Let us help you maximize your potash deposit potential!