Glass is one of the commonly used materials in people's production and daily life. It is widely used in construction, chemical, medical, automotive, engineering, instrumentation, and other industries.

Waste glass is on the rise due to the popularization of glass. Meanwhile, the recycling of glass waste reduces the discharge of garbage, achieves the goal of environmental protection, and brings good benefits for investment users.

Manual glass recycling is costly and not conducive to your health, so a glass crusher becomes your optimal choice.

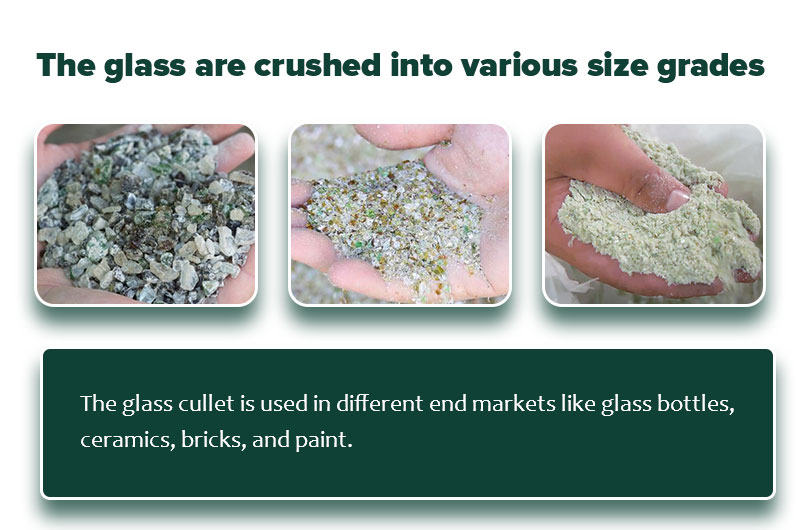

The glass crusher can process various waste glass such as glass pieces, glass bottles, automobile glass, bulletproof glass, industrial glass tubes, ceramics, bricks, paint, and other glass products into various size grades of pebbles,glass sand, powder, etc.

There are five types of glass crushers: jaw crusher, hammer crusher, roll crusher, impact crusher, and compound crusher.

Starting from the above five types of glass crushers, this article will analyze the advantages and disadvantages of these glass crushing machines to help you choose the suitable glass crusher.

1. Glass jaw crusher

A glass jaw crusher is ideal for bars, restaurants, hotels, nightclubs, recycling centers, holiday parks, and sports clubs.

Ftmmachinery specially designed various large, medium, and small glass crushers. Every hour it can crush more than 1, 500 bottles, with volume reductions of up to 80%.

Glass jaw crusher price: $1, 000 Get Latest Price

Advantages of glass jaw crusher

Small footprint, large inlet, and adjustable outlet, safe and easy to operate.

Small footprint, large inlet, and adjustable outlet, safe and easy to operate.

It has a deep crushing cavity, a large crushing ratio, and a wide range of applications, thus glass with different hardness like beer bottles and car glass windows can be crushed by squeezing, grinding and other methods.

It has a deep crushing cavity, a large crushing ratio, and a wide range of applications, thus glass with different hardness like beer bottles and car glass windows can be crushed by squeezing, grinding and other methods.

A semi-closed vertical curtain at the feeding port is designed to prevent the splash of crushed glass and play the role of noise reduction and dustproof sealing.

A semi-closed vertical curtain at the feeding port is designed to prevent the splash of crushed glass and play the role of noise reduction and dustproof sealing.

It is a highly productive glass crusher with a capacity of 1 to 2, 200 tons per hour. And it has a complete series of models to meet the different needs of users.

It is a highly productive glass crusher with a capacity of 1 to 2, 200 tons per hour. And it has a complete series of models to meet the different needs of users.

Disadvantages of glass jaw crusher

The vulnerable jaw plate surface will directly affect the crushing work as soon as the machine starts running. Therefore, the operator should monitor the jaw plate status in time to control the discharge size within the specified range.

Main parameters of glass jaw crusher

| Type | Model | Max. feed size (mm) | Discharging range (mm) | Capacity (t/h) | Glass bottles per hour |

| Primary crushing | PE-150×250 | 125 | 10-40 | 1-3 | 1, 500-5, 000 |

| PE-200×300 | 180 | 15-50 | 2-6 | 3, 000-10, 000 | |

| Secondary crushing | PEX-150×750 | 120 | 18-48 | 8-25 | 8, 000-40, 000 |

| PEX-250×750 | 210 | 25-60 | 13-35 | 12, 000-55, 000 |

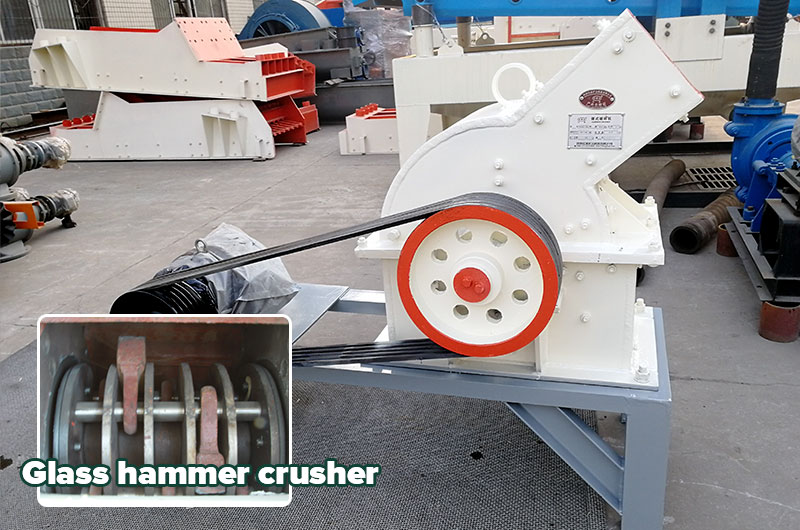

2. Glass hammer crusher

A glass hammer crusher is the best machine for making glass sand. Anyone can easily and quickly crush glass bottles into sand, no matter what colors bottles are.

Glass hammer crusher price: $976 Get Latest Price

Advantages of glass hammer crusher

One-time crushing without secondary crushing and shaping process. The discharging particle size is small, uniform, and cubic with less over-crushing. This glass sand is one of the best aggregates.

One-time crushing without secondary crushing and shaping process. The discharging particle size is small, uniform, and cubic with less over-crushing. This glass sand is one of the best aggregates.

Glass is easily crushed by the impact force of the high-speed hammerhead. Thus the hammerhead should have a strong wear resistance. Ftmmachinery Hammer Crusher can exactly meet this standard.

Glass is easily crushed by the impact force of the high-speed hammerhead. Thus the hammerhead should have a strong wear resistance. Ftmmachinery Hammer Crusher can exactly meet this standard.

Output size can be controlled by adjusting the grate gap at the discharge port. The glass crusher has a wide range of applications, advanced structural design, small footprint, low noise, and little pollution.

Output size can be controlled by adjusting the grate gap at the discharge port. The glass crusher has a wide range of applications, advanced structural design, small footprint, low noise, and little pollution.

Disadvantages of glass hammer crusher

The glass hammer crusher is prone to blockage when processing sticky and wet glass materials, thus causing downtime (the moisture content of the materials should not exceed 10%).

While crushing dry glass materials, it is easy to produce dust. Dust will enter the bearing and mix with the grease, resulting in poor lubrication and the bearing damage.

Main parameters of glass hammer crusher

| Model | Feed size (mm) | Output size (mm) | Capacity (m³/h) | Power |

| PCΦ400×300 | 200 | 25 | 5-10 | 4P 11KW |

| PCΦ600×400 | 250 | 30 | 10-22 | 4P 22KW |

| PCΦ800×600 | 300 | 35 | 18-40 | 6P 55KW |

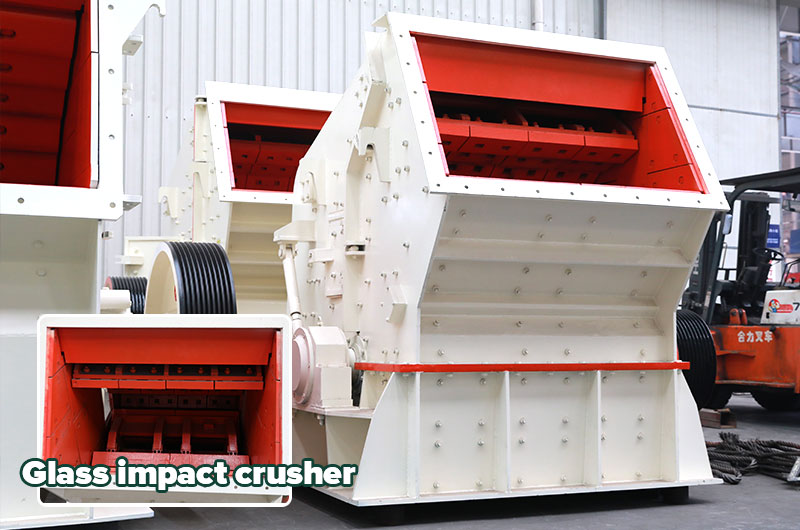

3. Glass impact crusher

A glass impact crusher is a multipurpose, larger-capacity glass crusher. It is designed for hard use with volume reductions of up to 80%.

Glass impact crusher price: $1, 000Get Latest Price

Advantages of glass impact crusher

It handles high-moisture glass waste. The heating device installed on the feeding port and impact plate greatly reduce the glass material that contains too much water.

It handles high-moisture glass waste. The heating device installed on the feeding port and impact plate greatly reduce the glass material that contains too much water.

It has a big impact force. It can crush glass with high hardness without causing any serious damage to the impact crusher.

It has a big impact force. It can crush glass with high hardness without causing any serious damage to the impact crusher.

It can effectively control the discharge size by adjusting the rotor speed, the impact type, and the gap of the grinding chamber.

It can effectively control the discharge size by adjusting the rotor speed, the impact type, and the gap of the grinding chamber.

The crusher wears very little during the crushing, as it hits the front of hammer plate without any touch with the back and sides of machine. And the grinding rod is very convenient to replace, saving your time and effort and reducing equipment downtime.

The crusher wears very little during the crushing, as it hits the front of hammer plate without any touch with the back and sides of machine. And the grinding rod is very convenient to replace, saving your time and effort and reducing equipment downtime.

Disadvantages of glass impact crusher

Due to the large hammerhead of the impact crusher, its balance needs to be calibrated during installation, otherwise, the vibration force of the machine during operation will be too large, which may be dangerous.

Main parameters of glass impact crusher

| Model | Specification (mm) | Feed port size (mm) | Max. feed size (mm) | Capacity (t/h) | Dimensions (Length×Width×Height) (mm) |

| PF-1007 | Φ1000×700 | 400×730 | 300 | 30-70 | 2330×1660×2300 |

| PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-90 | 2370×1700×2390 |

| PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 2680×2160×2800 |

| PF-1214 | Φ1250×1400 | 400×1430 | 350 | 80-180 | 2650×2460×2800 |

4. Glass compound crusher

A glass compound crusher is very suitable for restaurants, communities and other occasions. It is an ideal crusher for breaking high moisture glass materials.

Glass compound crusherprice: $1, 000Get Latest Price

Advantages of glass compound crusher

It is designed with no screen to crush the high-moisture glass materials without blockage. The water content of materials can reach 8%.

It is designed with no screen to crush the high-moisture glass materials without blockage. The water content of materials can reach 8%.

It adopts an elastic adjustment mechanism to discharge the unbreakable materials automatically without causing any damage to the crusher.

It adopts an elastic adjustment mechanism to discharge the unbreakable materials automatically without causing any damage to the crusher.

Its working performance is less affected by the material moisture. The product is cubic and has a large bulk density and small iron pollution, improving glass recycling.

Its working performance is less affected by the material moisture. The product is cubic and has a large bulk density and small iron pollution, improving glass recycling.

It has less noise (lower than 75 decibels), and less dust pollution.

It has less noise (lower than 75 decibels), and less dust pollution.

Disadvantages of glass compound crusher

As it is designed with a vertical structure, the glass materials may not be repeatedly crushed at a fast-passing speed, and a good crushing effect cannot be guaranteed for glass pieces.

Main parameters of glass compound crusher

| Model | Capacity (t/h) | Power (kw) |

| 800 | 5-15 | 4p 30kw |

| 1000 | 10-30 | 4p 55kw |

| 1250 | 20-60 | 6p 90kw |

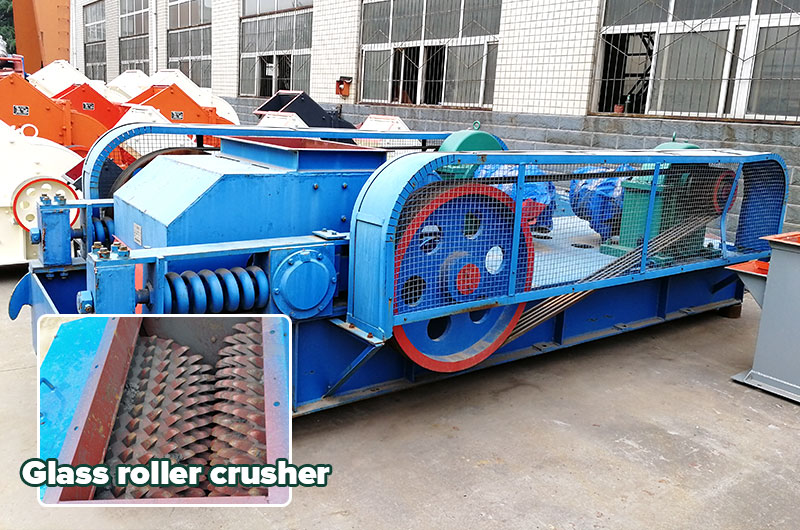

5. Glass roll crusher

A glass roller crusher is one of the most economical and practical glass crushers. It can handle the first and second crushing of wet or sticky glass materials.

Glass roller crusher price:$3, 500 Get Latest Price

Advantages of glass roller crusher

It has an extremely high output. The output can be increased by 30-40% when crushing glass bottles. And it saves more energy during the crushing process.

It has an extremely high output. The output can be increased by 30-40% when crushing glass bottles. And it saves more energy during the crushing process.

It crushes glass by squeezing and has an easy adjustable discharge port to meet different output needs.

It crushes glass by squeezing and has an easy adjustable discharge port to meet different output needs.

Simple design, small footprint, easy to install and replace parts.

Simple design, small footprint, easy to install and replace parts.

Equipped with a dustproof board, splash-proof feed hopper, and protective cover, it avoids the splash of glass dust. It also ensures the safety of operator and further improves the crusher performance.

Equipped with a dustproof board, splash-proof feed hopper, and protective cover, it avoids the splash of glass dust. It also ensures the safety of operator and further improves the crusher performance.

Disadvantages of glass roller crusher

It performs not well on crushing glass flakes as the flakes will leak through the gap between rollers, reducing the crushing effect. Meanwhile, the roller surface is easily damaged, resulting in an uneven crushing force.

Main parameters of glass roller crusher

| Model | 2PG0425 | 2PG0640 | 2PG0740 | 2PG0850 |

| Roller diameter (mm) | Ф400 | Ф600 | Ф700 | Ф800 |

| Roller width (mm) | 250 | 400 | 400 | 500 |

| Feed size (mm) | ≤25 | ≤25 | ≤25 | ≤25 |

| Output size (mm) | 2-8 | 2-8 | 2-8 | 2-8 |

| Capacity (t/h) | 5-10 | 10-20 | 15-30 | 20-40 |

| Motor power (kw) | 5.5×2 | 15×2 | 30×2 | 45×2 |

The above five types of crushers are the main equipment for glass crushing. Glass can be crushed by a single crusher or a combination of multiple devices. How to choose a glass crusher to obtain optimal crushing effect depends on your needs.

Ftmmachinery provides you with free online services like testing service, the latest quotation, and customized machine parameters. Please contact us if you have any questions. Welcome to visit our factory!