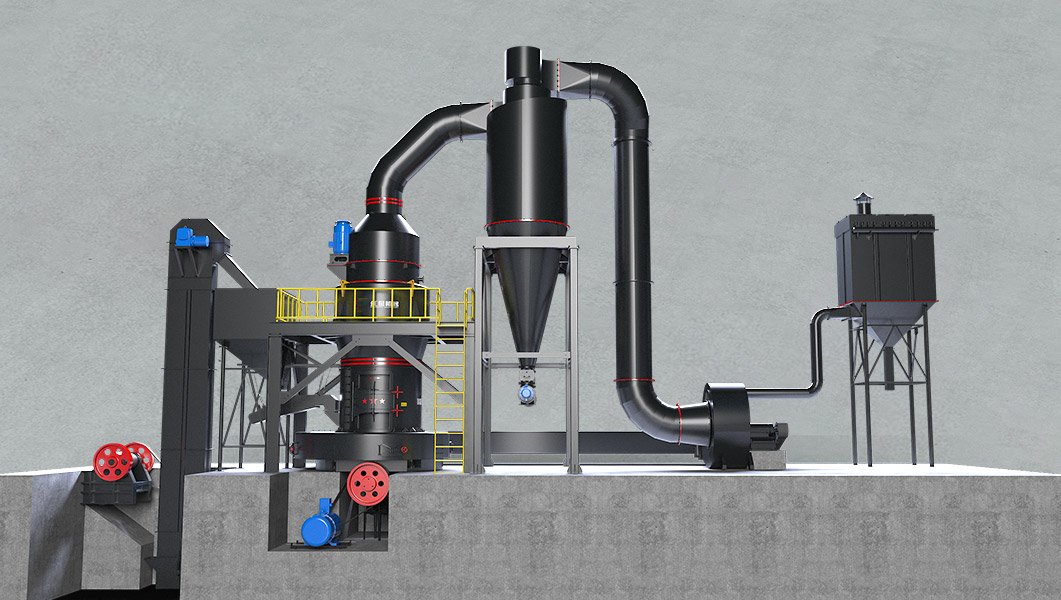

The powder grinding machine is a grinding mill that can efficiently grind rocks, minerals, or coal. The resulting powders are essential for industries like coal, cement, construction, steel, electricity, and energy.

We Provide Economical and Reliable Grinding Solutions

Whether soft rock, hard rock, non-metallic minerals, or coal, FTM Machinery can provide cost-effective grinding solutions.

Our powder milling machines are particularly suitable for producing clean coal powder, limestone powder, gypsum powder, quartz powder, calcium carbonate powder, marble powder, barite powder, mica powder, and bentonite powder.

Powder grinding machine

We Produce Powders of Different Particle Sizes

Our powder milling system produces coarse, fine and ultra-fine powders. All grinding mills can precisely adjust the powder fineness from 80 mesh to 3,000 mesh.

Powders of different fineness can be widely used in various applications, such as building materials (cement, concrete, etc.), industrial additives, soil additives, ceramics, glass, fertilizers, paints, coatings, and medicines.

FTM Machinery Powder Grinding Mills for Sale

Powder Grinding Mill

①Raymond Mill: $14,600/set (the lowest price)

- Applicable materials: Materials with humidity below 8%, such as non-metallic minerals (e.g., limestone, gypsum, calcium carbonate, barite, marble, kaolin), rocks, cement, coal, steel slag, and glass.

- Feed size: ≤30 mm

- Output size: 0.173–0.033 mm (80–325 mesh)

- Capacity: 0.6–176 tons/shift (8 hours)

- Advantages: High screen passing rate (>99%), stable output, low investment, ideal for small to medium production.

②Ultrafine Grinding Mill: $14,600/set (the lowest price)

- It is an upgraded Raymond mill for making micro powder and fine powder.

- Widely applied in metallurgy, mining, chemical, cement, construction, refractory materials, ceramics, and other industries.

- Feed size: <40 mm

- Output size: 0.25–0.015 mm (60–800 mesh)

- Capacity: 0.4–40 t/h

- Advantages: High grinding efficiency, high screening rate, durable grinding rollers (3–5), dual frequency analyzer for fineness control, no dust pollution.

- Applicable materials: Coal, cement raw material, clinker, slag, quicklime powder, steel slag, manganese ore, etc.

- Famous for its large output and high fineness. The output is 2–420 t/h and the fineness is up to 2,500 mesh.

- With its drying system, it can process materials with 15% humidity. The moisture content of the finished product is as low as 1%.

- Frequency conversion adjusts the powder fineness, with a screening rate of 97%.

- Low vibration, low noise, and no dust spillage.

Auxiliary Equipment

Bucket Elevator: $4,000/set (the lowest price)

- It is designed to convey dry powder vertically from the hopper to the mill with minimum space and maximum safety.

- Not for wet, sticky, or clumping materials.

- Lifting height: 25–80 m

- Capacity: 3–109 t/h

Guide to Powder Grinding

Popular Powder Milling Plants

- 10 Best Sold Mineral Grinding Plants

- Gypsum Powder Production

- Dolomite Rock Grinding Plant

- Quartz Grinding Plant

- Talc Fine Grinding and Ultrafine Grinding

- Limestone Powder Grinding Line

- Marble Powder Grinding in Pakistan

- Kaolin Clay Grinding Process and Grinding Mills

- Bentonite Grinding Process

- Mica Grinding

- Phosphate Rock Grinding

- Calcium Carbonate Grinding