The stone crusher machine is the machine used for crushing ore, concrete, and other building materials into specific particle sizes. It provides high-quality sand and gravel aggregates for industries such as mining, construction, roads, and waste disposal.

FTM Machinery crusher machine includes the primary crushers, secondary and tertiary crushers, sand making machines, vibrating screens, stone washers, and conveyor belts, forming a complete aggregate plant.

Stone crusher plant

A Small Stone Crusher Plant Can Afford It

FTM Machinery offers various stone crushing equipment at an affordable price for large, medium, or small mining companies, especially for artisanal miners, junior miners, and amateur mining enthusiasts.

We can process most ores, such as granite, iron ore, gold ore, limestone, quartz, river pebble, granite, bauxite, molybdenum ore, talc, silica sandstone, gypsum, dolomite, manganese ore, clay, nickel ore, etc.

Even with a small budget, many of our crushing machines allow you to process just a few kilos (pounds) each day and run your own small benefitable production line.

FTM Machinery Stone Crushers for Sale

Based on different materials and particle sizes, you can customize the best-performance stone crusher plant at an affordable price. Whether it is a fixed crusher or a mobile crusher, it can meet all your crushing needs.

1. Transportation and Feeding Equipment

This can be done by hand/shovel for very small-scale mining.

①Vibrating Feeder: $1,000/set (the lowest price)

- It can feed materials to the primary crushers evenly and continuously.

- Feed size: ≤1,500 mm

- Capacity: 400–2,040 tons/hour

② Belt Conveyor: $100/set (the lowest price)

- It automatically transports materials over long distances in crushing and sand making plants.

- Conveying length: 10–50 m

- Conveying capacity: 30–3,000 t/h

- Durable belt, automatic unloading, solving the problem of manual transport.

2. Crushing Machines

① Jaw Crusher: $1,000/set (the lowest price)

- Primary crusher for coarse crushing of rock materials, regardless of hardness or moisture (e.g., granite).

- Jaw stone crusher crushes rocks intermittently by squeezing between a fixed and movable jaw.

- Simple structure with jaw plates made of durable high manganese steel.

- Feed size: ≤1,200 mm

- Capacity: 1–1,435 tons/hour

- Used for primary crushing of medium to high hardness materials with low water content.

- Large feed particle size, reaching 1,350 mm

- High crushing efficiency with an output of 2,018–8,898 t/h, ideal for large-scale production.

③ Cone Crusher: $5,000/set (the lowest price)

- Used for medium, fine, and ultra-fine crushing of hard rocks, minerals, and construction waste like granite, pebble, gold ore, quartz, and concrete.

- Single-cylinder Cone Crusher : Low-budget option, easy to maintain with one hydraulic cylinder. The maximum feed size is 480 mm. The output size is 6–44 mm. The capacpty can reach 2,181 t/h.

- Multi-cylinder Hydraulic Cone Crusher : High-end option. Features multiple hydraulic cylinders. Its maximum feed size is 280 mm, with the output size of 3–64 mm. The capacity is up to 1,100 t/h.

- Fully Hydraulic Cone Crusher : Ideal for various large, medium and small crushing plants. The maximum feed size is 215 mm. The output size ranges from 3 to 64 mm, with finely shaped output. The capacity is 36–650 t/h.

④ Impact Crusher: $1,000/set (the lowest price)

- It uses impact energy to perform medium and fine crushing of materials.

- Applicable materials: Soft and water-rich materials, such as ores (dolomite, calcite, limestone, etc.), concrete asphalt, and construction waste.

- Maximum feed size: 800 mm

- Large crushing ratio and excellent cubic particle shape with sizes ranging from 2–10 mm.

- Maximum capacity: 2,000 t/h

⑤ Hammer Crusher: $976/set (the lowest price)

- Used for medium and fine crushing of medium hard and brittle materials, such as glass, limestone, and coal.

- Simple structure, large feed size, and output, ideal for large-scale crushing plants.

- Large crushing ratio of 10–50, one-time crushing and shaping, eliminating primary crushing.

- The discharging size is small, uniform, and cubic with less over-crushing.

- Available models:

a. PC Hammer Crusher: The feed size is within 300 mm. The output is 3–95 t/h.

b. PCZ Heavy Hammer Crusher: Larger feed size (within 1,000 mm), larger output (3,000 t/h), and 0–40 mm output size.

c. PCX Heavy Hammer Crusher: The feed size is within 300 mm. The capacity is 30–1,200 t/h. The output size is finer than PCZ series.

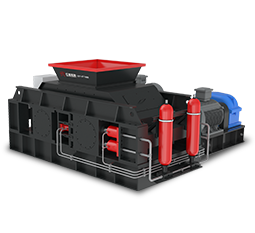

⑥ Roller Crusher: $3,500/set (the lowest price)

- The roller crusher is one of the most economical and practical crushers.

- It is used for medium and fine crushing of brittle, wet, and sticky materials like coal, clay, limestone, slag, and cement clinker.

- Capacity: 5–600 t/h

⑦ Double Toothed Roll Crusher: $6,500/set (the lowest price)

- It is a roller crusher that crushes materials by continuously squeezing between two toothed rollers.

- Used for the crushing and sand making of medium-hard and wet materials in small and medium aggregate plants, such as coal and pebbles.

- Feed size: ≤30 mm

- Output: 3–110 t/h

- Final product size: Adjustable (2–8 mm), cubic, less over-crushing

- Compared with other crushers, it is cheap, environmentally friendly, and has low crushing noise and power consumption.

- No screen bars, especially suitable for medium and fine crushing of high-moisture materials.

- Also used for sand making, high sand output ratio.

- Feed size: ≤100 mm

- Adjustable output size (0–5 mm), uniform, low over-crushing rate.

- Capacity: 5–100 t/h

- Used in crushing and sand making plants.

- It performs fine crushing of brittle materials with hardness below 9, such as cement, limestone, marble, talc, calcite, dolomite, kaolin, coal, gypsum, etc.

- Capacity: 5–260 t/h

- Output size: 0–10 mm

⑩ Sand Making Machine: $1,000/set (the lowest price)

- Sand making and shaping of limestone, river pebbles, granite, and other materials.

- Feed size: <55 mm

- Output size: 0–20 mm, cubic, providing high-quality aggregates for highways, municipal engineering, and concrete mixing plants.

- Capacity: 50–703 t/h

- Types of sand makers:

a. High requirements for the finished product and sufficient budget—HVI sand making machine

b. High-cost performance—VSI sand making machine

c. Mobile operation—Mobile sand making machine

- Applicable materials: Gold ore, iron ore, copper ore, molybdenum ore, lead-zinc ore, aluminum ore, magnesium ore, and other metal ores.

- Advantages: High output, uniform particle size, durable high manganese steel hammer and lining, environmentally friendly and energy-saving.

- Output size: Adjustable within 10–100 mm by replacing the screen.

3. Stone Screening Equipment

- Vibration intensity up to 6.0G, high screening efficiency.

- Large output: 12–1,800 t/h

- Various screen sizes: The number of sieve layers is 1–4. The screen size is 1–140 mm.

- Types: Circular vibrating screen, elliptical vibrating screen, and linear vibrating screen.

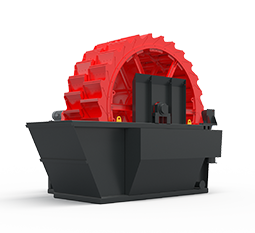

4. Sand Washing Machine

Sand Washing Machine: $6,000/set (the lowest price)

- Wash and dehydrate materials with high mud content to remove impurities such as stone powder and soil and improve the aggregate quality.

- Often used in conjunction with sand making machines to obtain the best artificial sand.

- Capacity: 5–300 t/h

- Types of sand washers:

a. Wheel sand washing machine: High washing efficiency, small footprint, water-saving, and durable.

b. Spiral sand washing machine: It washes more cleanly, but more fine sand is lost.

How to Choose the Type of Crushers?

How to Choose the Right Sand Making Machine and Sand Washing Machine?

Rock Crusher Maintenance

Best Sold Stone Crusher plant

- Top 10 Stone Crusher Plants for Sale

- Top 10 Sand Making Lines for Sale

- Aggregate Crushing and Processing

- Glass Recycling

- Price of Ballast Stone Crushing Machine in Kenya

- How to Crush Granite?

- How to Crush Coal?

- How to Crush Concrete?

- How to Crush Gabbro?

- Recycling Construction Waste

- How to Get High Purity Quartz Sand?

- Silica Sand Processing Plant

- How to Make Pebble Sand?

- How to Crush Stones?