From crushing, grinding and pulverizing, there are a lot of industry terminology out here, such as particle size, sieving analysis, mesh, microns, etc. It can be confusing. Do you know them well?

Particle size

What is particle size?

The particle size of the powder is called particle size. Due to the complexity of particle shape, we usually use the methods of sieving size, sedimentation particle size, and equivalent volume particle size.

Particle size is generally expressed by mesh. And it is popular in the world to use the calculated diameter of the equivalent volume of particles to express the particle size, with μm or mm as the unit.

What is size reduction?

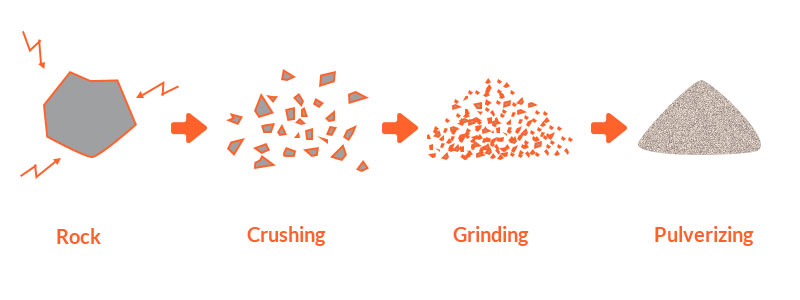

The definition of size reduction is the micronization and milling process to generate a more consistent particle size distribution. Put simply, size reduction is to make the large particles into small particles.

- 1Crushing: It is to crush the large rocks and stones by a rock crusher into gravel-sized materials (about 0-4 mesh);

- 2Grinding: It is to grind the particles to table salt size (5 to 25 mesh);

- 3Pulverizing: It is to reduce the particles by milling equipment into fine powders (25 mesh and beyond).

Mesh and microns

What is mesh?

The number of meshes is the number of holes in the screen, which is the number of holes per square inch. Sieving size is the size of sieve holes that particles can pass through the sieve, that is, mesh.

For example, a 50-mesh screen means that there are 50 holes within one inch of the screen. 500-mesh means 500 holes. Therefore, the higher the number of meshes, the more the number of holes within one inch of the screen.

What is micron?

Micron, also called a micrometer, is the metric unit of measurement for 0.001 millimeters. It usually refers to the particle size of the powder (the maximum length of the particle). The smaller the number of microns is, the finer the material is.

Mesh to microns and mesh to mm

Generally speaking, the number of meshes × aperture (number of microns) ≈ 15000. For example, 60-mesh particles are smaller than 40-mesh particles, and 80-mesh particles are extremely fine.

Therefore, the mesh number is a measure of particle size. The higher the number of meshes, the finer the particles.

The table below shows the conversions between mesh to microns and mesh to mm by adopting the U.S. Sieving Size and Tyler Equivalent (Tyler Mesh Size).

| U.S. Sieving Size | Tyler Equivalent | Microns | Mm | Inches | Term |

| No. 4 | 4 Mesh | 4760 | 4.76 | 0.1875 | Crush |

| No. 6 | 6 Mesh | 3360 | 3.36 | 0.1523 | Grind |

| No. 8 | 8 Mesh | 2380 | 2.38 | 0.0937 | |

| No. 10 | 9 Mesh | 2000 | 2.00 | 0.0787 | |

| No. 12 | 10 Mesh | 1680 | 1.68 | 0.0661 | |

| No. 14 | 12 Mesh | 1410 | 1.41 | 0.0555 | |

| No. 16 | 14 Mesh | 1190 | 1.19 | 0.0469 | |

| No. 18 | 16 Mesh | 1000 | 1.00 | 0.0394 | |

| No. 20 | 20 Mesh | 841 | 0.841 | 0.0331 | |

| No. 25 | 24 Mesh | 707 | 0.707 | 0.0228 | Pulverize |

| No. 30 | 28 Mesh | 595 | 0.595 | 0.0232 | |

| No. 35 | 32 Mesh | 500 | 0.500 | 0.0197 | |

| No. 40 | 35 Mesh | 420 | 0.420 | 0.0165 | |

| No. 45 | 42 Mesh | 354 | 0.354 | 0.0138 | |

| No. 50 | 48 Mesh | 297 | 0.297 | 0.0117 | |

| No. 60 | 60 Mesh | 250 | 0.250 | 0.0098 | |

| No. 80 | 80 Mesh | 177 | 0.177 | 0.0070 | |

| No. 100 | 100 Mesh | 149 | 0.149 | 0.0059 | |

| No. 120 | 115 Mesh | 125 | 0.125 | 0.0049 | |

| No. 140 | 150 Mesh | 105 | 0.105 | 0.0041 | |

| No. 200 | 200 Mesh | 74 | 0.074 | 0.0029 | |

| No. 230 | 250 Mesh | 63 | 0.063 | 0.0024 | |

| No. 270 | 270 Mesh | 53 | 0.053 | 0.0021 | |

| No. 325 | 325 Mesh | 44 | 0.044 | 0.0017 | |

| No. 400 | 400 Mesh | 37 | 0.037 | 0.0015 | |

| No. 800 | 800 Mesh | 15 | 0.015 | 0.0006 |

Fineness Modulus

Coarse and fine aggregate

According to the magnitude of particle size, we can divide materials into coarse and fine styles. Different functions of particle sizes have different boundary dimensions of the coarse and fine aggregates.

The particle size larger than the boundary size is coarse aggregates. The rest is fine aggregates.

- Cement concrete: The boundary size is 4.75 millimeters. The aggregates with a particle size greater than 4.75 mm are coarse aggregates (stone). Those smaller than 4.75 mm and greater than 0.15mm are fine aggregates (sand);

- Bituminous mixture: The boundary size is 2.36 millimeters;

- Gravel and sand: The boundary size is 2 millimeters. The aggregates with a particle size greater than 2 mm are gravel (stone); those smaller than 2 millimeters are sand. Gravel sand refers to sand in which the content of gravel grain in sandstone accounts for 25%-50% of the total mass (2mm).

Qualified fine aggregates have good grades of sand, including fineness modulus, firmness and mud content. Fineness modulus can measure the aggregate quality, as it affects the concrete workability, strength and impermeability.

Fineness Modulus

Fineness modulus (F.M.) can reflect the particle size of aggregates. The larger the fineness modulus, the thicker the fine aggregate. It is calculated by the sieving analysis with standard IS sieves.

sieving analysis allows materials to pass through a series of sieves with gradually decreasing mesh sizes to evaluate the particle size distribution.

Fineness modulus formula:

Cumulative % weight retained = (commutative weight retained / total weight) * 100%

F.M. = (total cumulative % weight retained) / 100

The fineness modulus of sand is divided into 4 levels. (Sand size in mm)

- Coarse sand size: Its fineness modulus is 3.1-3.7, and the average particle size is 0.5mm or more;

- Medium sand grain size: Its fineness modulus is 2.3-3.0, and the average particle size is 0.35-0.5mm;

- Fine sand size: Its fineness modulus is 1.6-2.2, and the average particle size is 0.25-0.35mm;

- Super-fine sand size: Its fineness modulus is 0.7-1.5, and the average particle size is 0.25mm or less.

The fineness modulus of cement ranges from 1.6 to 3.7, preferably medium or coarse sand plus a small amount of fine sand in a ratio of 4:1. For the particle size of cement, about 95% of cement is within 45 microns. And the average particle size is 15 microns.

Conclusion

Figuring out the industry terminology is very helpful for you. FTM is a professional manufacturer of all kinds of stone and sand processing equipment, helping you to process various sand and stone production line at the lowest cost.