When you think of calcination, rotary kilns come to mind. They're versatile, not just for cement or clay, but also as mineral reduction furnaces.

But do you truly understand them? Can you gauge their health from flame shape? Recognize signs of material agglomeration? Understand why refractory materials wear out?

This article has your answers.

Solution I: Diagnose flame shape in rotary kiln

FTM Machinery engineers have categorized rotary kiln flame shapes into six types, with the "lively" flame being the most preferred by operators, indicating optimal calcination efficiency and material quality.

However, there are five "abnormal" flame shapes, each with its reasons and solutions:

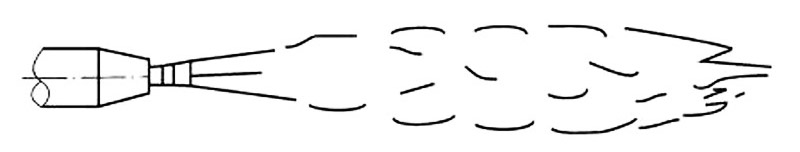

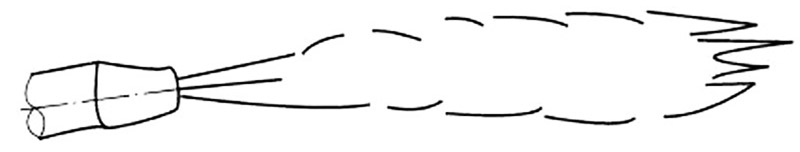

1. "Active flame" - normal flame

When the flame in the rotary kiln is lively and powerful, with suitable shape, length, and a black flame head, it signifies high calcination efficiency and optimal temperature, ensuring the best material quality.

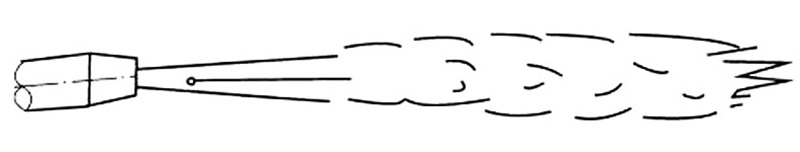

2. Long black flame - low combustion efficiency

A long black burner flame suggests low calcination efficiency, prompting checks on coal quality, equipment operation, and burner condition.

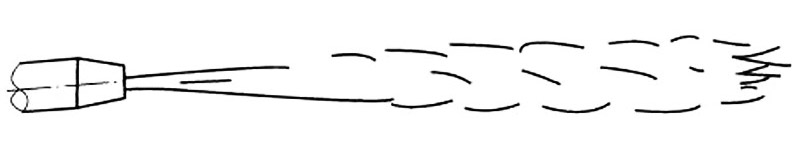

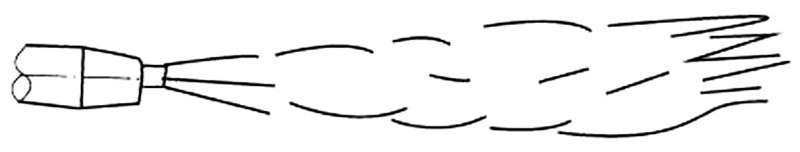

3. Slow flame - not always negative

A slow flame, with a dispersed shape, can mitigate excessive temperature or brick burning during operation.

4. Diffusion flame - requires adjustment

A short and thick diffusion flame may damage kiln lining or compromise material quality, necessitating checks on kiln conditions and air ratios.

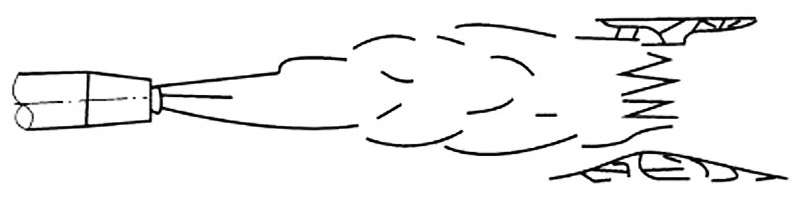

5. Touching kiln skin flame - excessive upward

Flames washing away kiln skin upward may shorten refractory brick life and reduce firing quality, demanding scrutiny of burner position and air volume.

6. Licking flame - excessive downward

Flames excessively close to materials can block heat transfer, leading to decreased clinker quality and increased coal consumption. Operators need to check burner position and alignment.

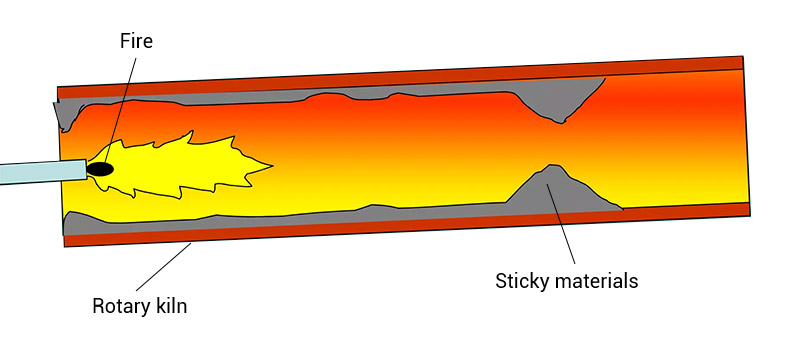

Solution II: Easily prevent kiln ring formation

Ensuring normal rotary kiln flame is one challenge; another is material looping.

This occurs when furnace charge adheres in a ring shape to the inner wall of the high-temperature zone. Minor adhesion is termed kiln skin, while thicker adhesion affecting furnace operation is called ring formation.

The knot ring is categorized into a front knot ring and a rear knot ring. The front knot ring forms in the cooling zone, while the rear knot ring forms at the junction of the fired zone and the transition zone.

FTM Machinery engineers highlight the clear signs, causes, and impacts of kiln ring formation, along with preventive and remedial measures.

1. Signs of ring formation

Similar to ants moving before rain, the rotary kiln may show signs of ring formation.

Uneven calcination and rubbing of materials may lead to abnormal white brightness, often accompanied by a distinct "dong-dong" sound.

2. Causes of ring formation

- Poor-quality coal with high ash content leads to incomplete combustion and ring formation.

- Excessive sulfur in coal causes severe kiln crusting, resulting in blockages and ring formation.

- Improper burner positioning or abnormal flames can create kiln skin, rings, or even "dome" formations.

- Unreasonable raw material plans cause agglomeration and blockages.

3. Impacts of ring formation

- Material blockages necessitate machine shutdowns for maintenance, reducing production efficiency.

- Abnormal agglomeration friction leads to kiln lining wear, shortening rotary kiln lifespan.

- Agglomerates falling into the cooler damage key components.

4. Prevention of ring formation

- Optimize batching plans with high saturation and silica rates to prevent ring formation and enhance calcination.

- Maintain appropriate kiln speed and output, control raw and fuel quality, and stabilize feeding operations to prevent looping.

- Reduce pulverized coal fineness to ensure full combustion and prevent ring formation.

5. Dealing with knotted rings

- Front knot rings: Concentrate high temperatures at the ring by pulling out the coal injection pipe, gradually burning it away.

- Rear knot rings: Use the cold firing method for thin rings. For thicker ones, apply the cold and hot alternating method by reducing feed and alternating hot and cold burns until the ring collapses.

Solution III: Importance of refractory materials

To ensure the long-term efficiency of rotary kilns, attention must be given to their refractory materials. FTM Machinery engineers provide insights into five key aspects:

1. Importance of Refractory Materials

Refractories shield kilns in three ways:

- Thermal Protection: They withstand high temperatures, preventing kiln damage.

- Chemical Resistance: They resist corrosive substances, safeguarding kiln and equipment integrity.

- Mechanical Durability: High wear resistance minimizes friction-induced wear, preserving kiln integrity.

2. Types of Refractory Materials

- Refractory Bricks: This category includes high alumina, silicon carbide, and alumina silicon carbide bricks. While silicon carbide bricks offer high heat resistance and hardness with low thermal conductivity, they are brittle. Alumina silicon carbide bricks offer excellent performance but at a higher cost.

- Refractory Castables: These are unshaped refractory materials typically applied by first welding "Y"-shaped anchors, then pouring the refractory material. Varieties include high aluminum, siliceous, and ductile iron castables.

- Spray Coating: This involves applying anti-corrosion coatings to the inner wall of the rotary kiln drum. Common options are aluminum oxide, chromium oxide, and silicon carbide coatings.

- Other Refractory Materials: These include ceramic fiber and silicate fiber used for heat insulation, sealing, and caulking of rotary kilns.

3. Signs of Refractory Wear

- Visible damage like cracks, flaking, roughness, thinning, or color changes on brick surfaces.

- Hot spots on the kiln shell indicate reduced insulation and heat conductivity to the shell.

- Decreased kiln airtightness impacts efficiency and heat control.

4. Causes of Refractory Wear

- Mechanical Stress: Thermal expansion, loose masonry, kiln opening/closing, and cylinder deformation.

- Thermal Damage: Overheating leading to melting, pitting, peeling, and cracking.

- Chemical Corrosion: Alkali, chromium, and redox corrosion.

5. Replacing Worn Refractory Materials

In case of localized damage to the refractory material impacting overall operation, complete dismantling and rebuilding pose significant time, cost, and environmental concerns.

Therefore, FTM Machinery engineers advocate for employing gunning technology for partial damage.

This involves cleaning the affected area and applying refractory material using high-velocity airflow, typically requiring only minutes to hours for repair and seamless production continuation.

6. Customization of Refractory Materials

FTM Machinery uses 70% high-aluminum bricks for their rotary kilns, known for stable chemical properties, thermal shock stability, wear resistance, and mechanical strength. This ensures efficiency, longevity, and user satisfaction, with options for customized refractory materials.

Solution IV: Maintain your rotary kiln regularly

Rotary kiln maintenance is vital for sustained production efficiency. FTM Machinery engineers offer six maintenance methods to prolong your kiln's service life:

1. Refractory Material Inspection and Replacement: Regularly check refractory bricks, ensuring uniformity and completeness of spray coatings and castables.

2. Bearings and Transmission Devices Lubrication: Regularly lubricate bearings, gears, and transmission devices. Monitor and replace aging lubricating oil and filters promptly.

3. Kiln Body Calibration: Check cylinder alignment, measure ovality and deformation, and make timely corrections and adjustments.

4. Thermal System Optimization: Install temperature sensors and adjust burner and nozzle positions as needed to enhance combustion efficiency.

5. Equipment Operating Status Monitoring: Conduct regular inspections to identify potential problems early, ensuring stable equipment operation.

6. Cleaning and Maintenance: Regularly clean dust and debris to prevent heat dissipation and equipment operation issues. Perform anti-corrosion treatment on susceptible parts to extend equipment life.