If boron suddenly vanished, chaos would ensue worldwide.

Initially, the absence of boron would deprive the human body of vital support, potentially escalating arthritis, osteoporosis, and other diseases, while impeding children's growth and development.

Furthermore, plant growth would decelerate, resulting in misshapen fruits and vegetables dominating the market, altering the taste and appearance of our produce.

Additionally, the aerospace industry and its associated productions would suffer immensely. The absence of boron would cripple high-end technological advancements and scientific explorations, rendering space exploration a distant luxury.

Boron in human body

If you're experiencing brittle nails, joint pain, muscle weakness, decreased immunity, or hair loss, it might be a signal from your body that you need to boost your boron intake. These are common symptoms of boron deficiency in humans.

Boron plays a crucial role in maintaining bone health and is often used to treat various types of arthritis.

The World Health Organization (WTO) recommends a daily intake of 1–13 mg of boron for the human body.

However, it's essential to be mindful of your boron intake as taking too much can lead to adverse reactions such as nausea, vomiting, indigestion, headache, and diarrhea.

Foods rich in boron include prune juice, avocados, grapes, peaches, apples, pears, and peanuts, among others. Below is a boron-rich foods chart.

| Food | Boron content |

| Prune juice | 21.5 mg/kg |

| Avocado | 22 mg/kg |

| Raisin | 19 mg/kg |

| Peach | 1.87 mg/kg |

| Grape juice | 2.02 mg/kg |

| Apple | 2.38 mg/kg |

| Pear | 1.22 mg/kg |

| Peanut | 13.8 mg/kg |

Boron in plants

What's going on with this leaf? Why is it all crinkled and yellow?

Well, it could be due to a boron deficiency. Boron is crucial for plant health. Without enough of it, flowers might struggle to pollinate and fruits could be in short supply.

That's why some people see boron as a key to feeding the world. It's not just about fruit production, though. Boron fertilizer can also help maintain the right PH in soil, fend off pests, and boost yields.

But getting boron fertilizer ready for action takes some work.

First, you've got to crush the boron ore with a jaw crusher, then grind it finely in a ball mill, and finally, turn it into granules with a granulator. If you want to dive deeper into the granulation process, check out our article "How To Make Granular Fertilizer?"

After all that, though, the fertilizer's still pretty wet. That's where a rotary dryer comes in handy, making it easier to store and transport. For more on drying boron fertilizer efficiently, take a look at our blog "How to Dry Fertilizer Efficiently?" or Contact Our Engineers.

Boron in minerals

Turkey possesses over 70% of the world's boron reserves, making it a significant player in the global market. Among the commercially valuable boron minerals, Borax, Kernite, Colemanite, and Ulexite stand out, collectively contributing to over 90% of the world's borate sources.

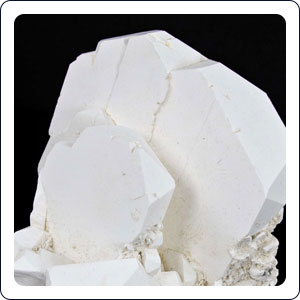

- Chemical formula: Na2B4O7·10H2O

- Color: Colorless or white

- Hardness: 2 to 2.5

- Luster: Oily

- Chemical formula: Na2B4O7·4H2O

- Color: Colorless or white

- Hardness: 2.5 to 3

- Luster: Vitreous to pearly

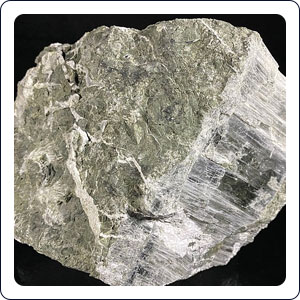

- Chemical formula: Ca2B6O11·5H2O

- Color: Colourless, white, yellowish, grey

- Hardness: 4 to 4.5

- Luster: Vitreous to adamantine

- Chemical formula: NaCaB5O6(OH)6·5H2O

- Color: Colorless or white

- Hardness: 2.5

- Luster: Vitreous

In the industrial sector, Borax, Kernite, Colemanite, and Ulexite are primarily processed into borax and boric acid.

Ulexite also finds application as a raw material in optical glass production.

Borax serves as a crucial ingredient in glassmaking, ceramics, detergents, and fireproof materials, while boric acid is widely employed in boron fertilizers, wood preservation, and metallurgical processes, among others.

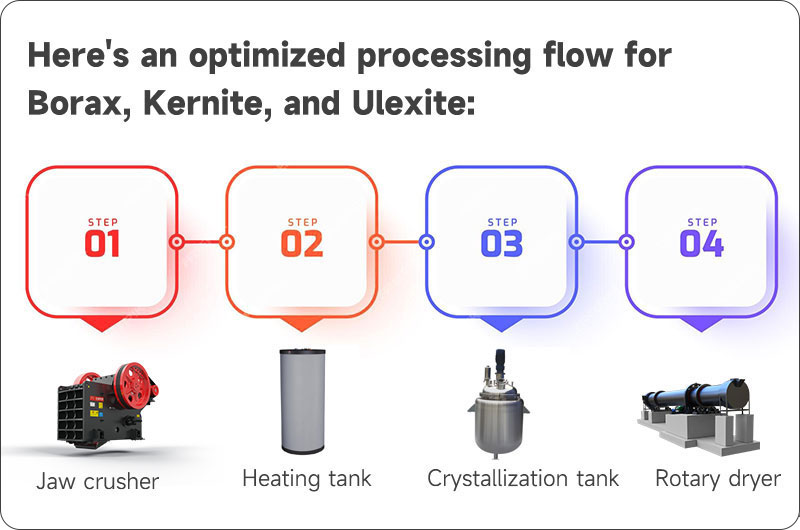

Here's an optimized processing flow for Borax, Kernite, and Ulexite:

The boron ore undergoes initial processing through a jaw crusher, fragmenting it into small particles. Following this, the ore is subjected to heating and dissolution.

The subsequent steps involve crystallization in specialized tanks and filtration to facilitate smooth borax crystallization. The final stage entails drying using a rotary dryer to obtain pure borax.

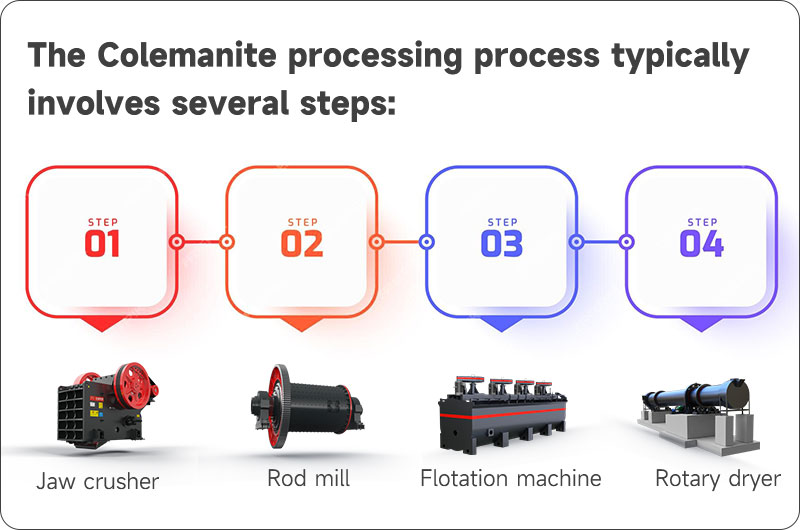

The Colemanite processing process typically involves several steps:

Similarly, first use a jaw crusher for crushing, then use a rod mill for fine grinding, then use sodium silicate and sodium oleate for flotation, and finally use a rotary dryer for drying to obtain high-purity borax.

Boron in the ecological industry

Boron plays a pivotal role in ecological advancements, primarily focusing on global decarbonization and facilitating waste recycling efforts.

In the pursuit of global decarbonization, boron contributes through various avenues:

- 1Energy Storage Technology: Borate batteries offer a solution to balance the intermittency of renewable energy sources, thereby reducing dependence on conventional power generation methods.

- 2Advanced Materials: Boron is harnessed to create lightweight, high-strength materials, which aids in reducing structural weight and energy consumption.

- 3Zero-Carbon Power Generation: Boron's effectiveness as a neutron absorber enhances the safety and reliability of zero-carbon emission nuclear power generation.

Boron also facilitates the recycling of waste materials through the following mechanisms:

- 1Metal Recycling Assistance: Borate serves as a combustion accelerant and forms slag when combined with metal oxides during recycling, such as fluoroboric acid aiding in aluminum recycling, thus cutting costs and enabling the use of low-melting-point furnaces.

- 2Lithium Extraction from Boron Waste: Lithium is extracted from boron waste using innovative techniques like roasting and three-phase extraction, already underway in pilot plants by companies like Rio Tinto and Etimax.

- 3Boron Glass Utilization: Boron glass effectively encapsulates high-radiation nuclear waste, ensuring its isolation from the environment. This approach, established in the 1970s, is recognized as a safe and efficient method for managing nuclear waste.