The process of limestone pelletizing is a method of transforming powdered limestone into granular products with specific shapes and sizes.

Pelletized limestone, also known as pelletized lime, is commonly used in the agricultural sector as a soil amendment to neutralize soil acidity and increase pH levels.

Why pelletized lime is better?

In agriculture, commonly used lime products include agricultural lime (ag lime), powdered lime, quicklime, hydrated lime, liquid lime, and lime slurry.

However, agricultural lime is coarse and uneven in size, usually taking 3–5 years to decompose effectively. Therefore, it requires a longer time to adjust soil pH and release nutrients.

Powdered lime is easily affected by wind during application, making it difficult to spread evenly. This can lead to dust pollution, resulting in inefficiency and waste, and failing to provide quality soil improvement.

In contrast, pelletized limestone has significant benefits:

- Easier to spread: Pelletized lime is heavier and less affected by wind. It can be evenly distributed on the soil surface and absorbed more effectively.

- Less pollution: Pelletized lime's consistent size and shape produce less dust, making it environmentally friendly.

- Increased nutrient absorption: Pelletized lime decomposes easily, providing long-term pH adjustment, and improving soil water retention and stability.

- Convenient transportation: Pelletized lime has higher density and smaller volume, making it less prone to caking. It is easier to handle and transport compared to powdered lime.

These unique advantages make pelletized lime increasingly the preferred choice for more agricultural operators.

The limestone pelletizing process

Here is a detailed description of the limestone pelletizing process:

Step 1: Crushing limestone rocks

For limestone with less than 5% clay content and less than 7% moisture content, FTM Machinery recommends using a hammer crusher for primary crushing.

If the raw limestone has a high clay content, it is recommended to use a trommel screen for pretreatment to remove the clay.

For limestone with over 7% moisture content or highly abrasive characteristics, a jaw crusher and impact crusher are typically employed, using a two-stage crushing process to efficiently complete the limestone crushing.

Step 2: Grinding limestone rocks

The crushed limestone needs to be sent to a mill for further fine grinding. FTM Machinery offers various options, including Raymond mills, ultrafine mills, and vertical roller mills.

The grinding process requires precise control over fineness, typically requiring the powder to reach 200 mesh (74 μm) or finer.

Choose according to your production needs: the Raymond mill handles up to 22 t/h, the ultrafine mill up to 44 t/h, and the vertical roller mill up to 200 t/h.

Step 3: Mixing with binder

Mixing limestone powder with only water produces fragile pellets. Therefore, it is necessary to mix the limestone powder with a binder to improve the hardness and stability of the limestone pellets.

Commonly used binders include lignosulfonate, which helps the limestone powder form a robust pellet structure during the pelletizing process.

Step 4: Pelletizing

The mixed material is fed into a disc pelletizer (also known as a disc granulator), where a suitable amount of water is sprayed while it continuously rotates. During this process, the limestone gradually agglomerates into limestone pellets.

Users can control the final pellet size by adjusting the machine's tilt angle (35°–55°) and rotation speed.

FTM Machinery's disc pelletizers produce high-quality limestone pellets, with over 90% of the pellets having a diameter between 3 mm and 6 mm, and they do not form large lumps.

Step 5: Drying and cooling

The pelletizing process increases the moisture content of the limestone pellets, necessitating drying.

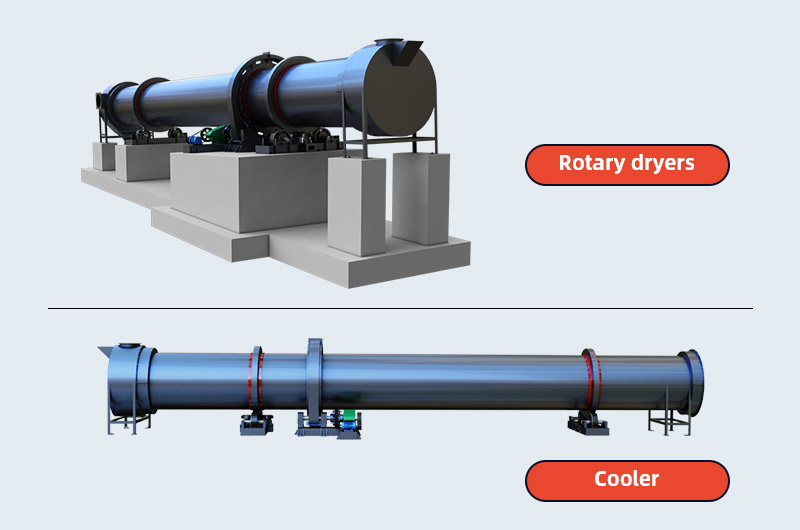

Rotary dryers are commonly used equipment for drying pelletized limestone. They handle large capacities (1.9 t/h – 76 t/h), offering high drying efficiency while preventing pellet clumping and enhancing hardness and stability.

Subsequently, limestone pellets can be cooled using a cooler as needed. Finally, qualified pelletized lime is accurately weighed and packaged for sale and transportation.

For over 40 years, FTM Machinery has been at the forefront of the pelletizing industry, accumulating extensive experience. Whatever your requirements, we can provide tailored process solutions for your materials.

For more information about our limestone pelletizing equipment, please contact us immediately! Feel free to consult