A crusher, also known as a stone crusher, is a machine that uses mechanical action to break large rocks, ores, or other raw materials into gravel or rock powder.

Crushers are widely used in ore crushing, aggregate production, construction waste recycling, and natural stone processing.

Different crushers have various crushing methods, and different stages of crushing require different types of crushers.

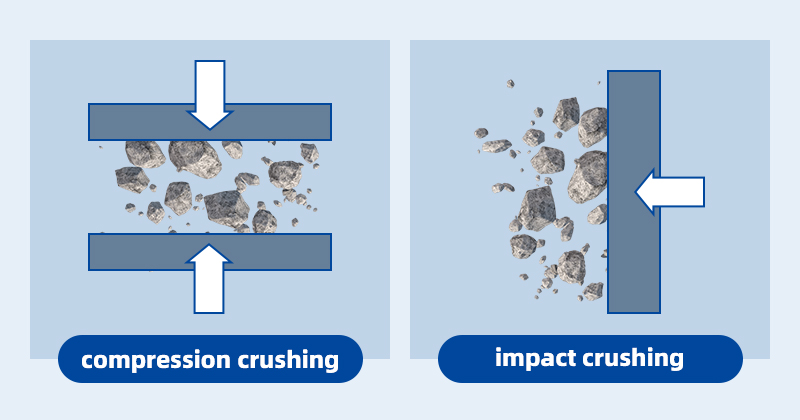

Two main ways of crushing

Crushers reduce the size of materials by applying mechanical force. In the mining and construction industries, the most commonly used crushing methods are compression crushing and impact crushing.

- Compression crushing: This method applies pressure to the material between two crushing surfaces, effectively squeezing it. It is used in jaw crushers, cone crushers, gyratory crushers, and roll crushers.

- Impact crushing: This method uses high-speed moving parts to strike the material, breaking it under the force of impact. This technique is employed in impact crushers, hammer crushers, sand making machines, fine crushers, and compound crushers.

Understanding material characteristics and defining production needs can help you choose the right crushing method, saving costs throughout the production process.

Types of crushers

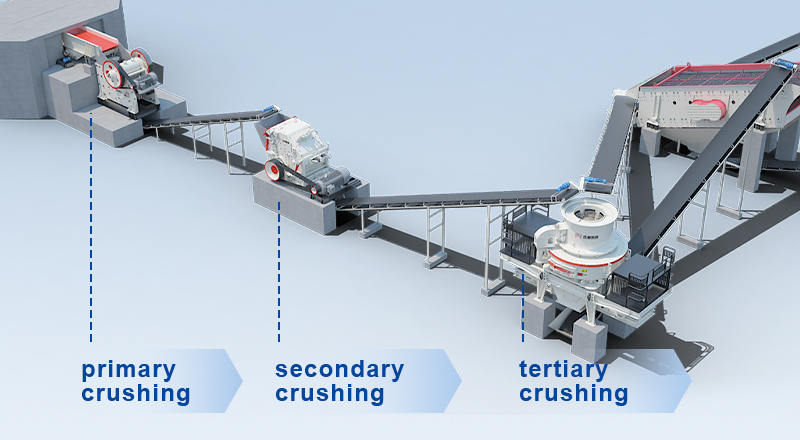

Crushing is a multi-stage process that includes primary crushing, secondary crushing, and tertiary crushing. Different types of crushing equipment are used at each stage to meet various crushing requirements.

Primary crushing breaks down large raw materials into medium-sized pieces for easier handling in subsequent processes. Next, secondary crushing reduces the material to smaller sizes. Finally, if needed, tertiary crushing further reduces the material to fine particles.

Here is an introduction to the different types of crushers used at each stage and their characteristics.

1. Primary crushing equipment

Primary crushing is the first stage of the stone crushing process. At this stage, raw materials extracted through blasting or mining are crushed to a size suitable for conveyor transport and downstream processing.

The three main types of primary crushers are jaw crushers, gyratory crushers, and hammer crushers.

Jaw Crusher

Jaw crushers use the compressive and bending action of a fixed jaw plate and a movable jaw plate to crush materials of various hardnesses.

When the two jaw plates come together, the material is crushed; when the plates move apart, material smaller than the discharge opening is released from the bottom. The crushing action is intermittent.

Jaw crushers have a wide range of output capacities, making them suitable for large, medium, and small crushing production lines. They are currently one of the best-selling crushers on the market.

The maximum feed size for a jaw crusher can reach 1,200 mm. They perform better than gyratory crushers on high-humidity, high-viscosity materials like clay, but often produce output with poorer particle shapes, such as flat, sharp, or triangular particles.

Gyratory Crusher

Gyratory crushers use the oscillating motion of the crushing cone to compress and crush hard ores and large materials, making them particularly suitable for high-hardness and abrasive materials.

They produce smaller particle sizes and can generate fine needle-like particles, but can only handle dry to slightly wet materials. Sticky materials may cause machine blockages.

With a maximum capacity of up to 8,898 t/h, gyratory crushers are highly effective in medium to large mining operations and construction material production lines, though they are relatively expensive.

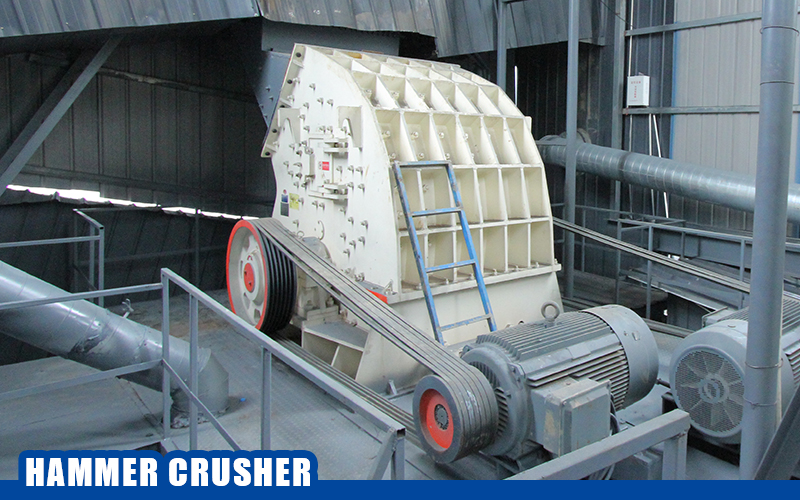

Hammer Crusher

Hammer crushers utilize high-speed rotating hammers to impact and crush materials. The crushed materials are then propelled at high speed towards the impact plate and grate bar, undergoing multiple impacts.

They can crush low to medium hardness materials such as limestone and coal, as well as materials with moisture content below 15%, suitable for both dry and wet crushing.

Hammer crushers have a reduction ratio of up to 50, a feed size of up to 1,000 mm, and a maximum output capacity of 3,000 t/h. They are energy-efficient, produce minimal over-crushing, and are designed for medium to large production lines.

2. Secondary crushing equipment

After primary crushing, secondary crushing equipment further processes medium-sized materials into smaller particles for subsequent processing or final use.

Secondary crushers include cone crushers and impact crushers.

Cone Crusher

Cone crushers utilize lamination crushing, where material enters the crushing chamber from the top and is compressed and ground into smaller particles between the moving cone and the fixed cone until it is discharged from the bottom.

Cone crushers are commonly used for medium, fine, and ultra-fine crushing stages of high and medium hardness materials like granite and basalt but are not suitable for softer or wet, sticky ores and stones.

The equipment produces a high proportion of cubic-shaped particles, exceeding 85%, with a maximum feed size of 480 mm, but it cannot handle overly large materials.

While cone crushers are relatively expensive, they have low operational costs, making them suitable for long-term operation in large quarries and mining operations.

Impact Crusher

Impact crushers use a high-speed rotating rotor and blow bars to strike the material. Inside the crushing chamber, the material is repeatedly impacted by the blow bars and impact plates until it reaches the desired size and is discharged from the bottom.

Unlike cone crushers used for high-hardness rocks, impact crushers are typically used for medium or fine crushing of medium-hard and brittle materials such as limestone and dolomite. They are often paired with jaw crushers for secondary crushing in sand and gravel production lines.

Impact crushers produce excellent cubic-shaped final products with minimal stone powder, ideal for applications requiring high-quality particle shapes. They handle feed sizes up to 800 mm and output capacities from 30 to 2,000 t/h.

They are affordable, suitable for budget-conscious users. However, the blow bars and impact plates wear out quickly when crushing hard rocks. The machine struggles with wet or muddy materials, making blockages hard to clear.

3. Tertiary crushing equipment / Fine crushing equipment

After primary and secondary crushing, big stones are turned into finished stone particles. If finer sand and gravel are needed, tertiary crushing is required.

Tertiary crushers are used for fine crushing and sand making, typically employing vertical shaft impact crushers (VSI), roller crushers, fine crushers, or compound crushers.

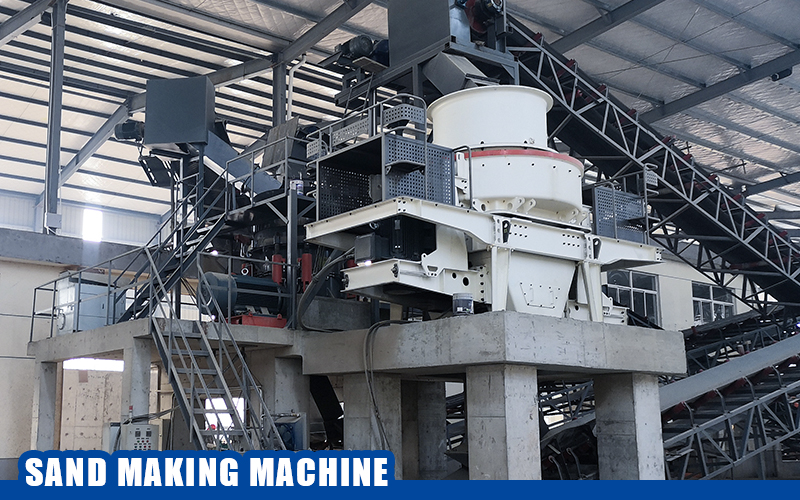

Vertical Shaft Impact Crusher (VSI) / Sand Making Machine

The VSI, also known as a sand making machine, is used to produce high-quality manufactured sand, with output capacities up to 703 t/h.

It is suitable for materials of various hardnesses, especially hard and abrasive materials like granite and river pebbles. The produced sand has excellent particle shape with very low flakiness, making it ideal for construction and road building.

During operation, the high-speed rotating impeller scatters and crushes the material, which then collides and grinds together before discharge. There are two crushing methods: rock-on-rock and rock-on-iron.

Roll Crusher

Roll crushers crush materials through the compression action of two rotating rollers. They are commonly used as tertiary crushers, widely applied in cement, mining, building materials, and abrasive industries for fine crushing and sand making.

Designed for medium to low hardness and brittle materials, they are effective for crushing sticky or moist materials (up to 30% moisture) like coal, limestone, and clay. They are the preferred equipment for coal crushing.

With a reduction ratio of 4:1, roller crushers have a lower ratio compared to other crushers, making them unsuitable for hard and highly abrasive materials due to rapid roller wear and increased operational costs.

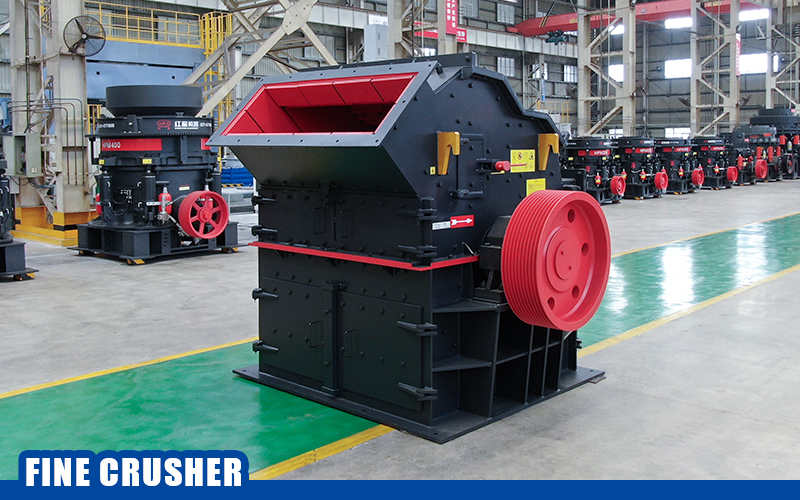

Fine Crusher

Fine crushers use high-speed hammers and impact plates to crush materials, which then fall onto the lower rotor and are thrown at high speed against the impact plates. This repeated process achieves ultra-fine results.

This machine is suitable for fine crushing and artificial sand making of medium-hard materials such as quartz, calcite, marble, iron ore, and granite, providing sand and gravel aggregates for roads, construction, and cement applications.

Compound Crusher

The compound crusher, a double-rotor primary impact crusher, is a new type of fine crushing and coarse grinding product launched by FTM Machinery.

Materials entering the high-speed rotating impeller are centrifugally thrown outward, colliding with other materials, then repeatedly colliding and grinding between the impeller and casing before finally discharging from the bottom.

This grateless equipment can crush and produce sand from hard and medium-hard, high-moisture, sticky materials. It is commonly used for fine crushing in small to medium-sized cement plants.

In sand making, it is renowned for its high sand production ratio (0–5 mm). In 800 and 1000 specifications, it shows exceptionally high sand production rates, making it indispensable in sand production lines.

Choosing the optimal crusher for your project

To ensure the smooth progress and achieve expected production efficiency and product quality, choosing the right crusher is crucial.

Here are key factors to help you make the best choice:

1. Material type

- Hardness: Hard materials like granite and basalt are suitable for jaw crushers or gyratory crushers, while softer materials like limestone and coal can opt for impact crushers or hammer crushers.

- Abrasiveness: Materials with high abrasiveness like iron ore require crushers with good wear resistance, such as cone crushers.

- Moisture content: For materials with high moisture content, choose equipment with strong adaptability to moisture, like roller crushers and hammer crushers.

2. Application sites

- Fixed crushers are not suitable for projects requiring frequent site changes but are ideal for mines and large construction projects due to their sturdy structure, high processing capacity, and low maintenance costs.

- Mobile crushers and portable crushers are ideal for projects requiring site flexibility, such as construction waste processing, road construction, and small-scale mining. They are easy to install, highly mobile, and versatile, enabling quick deployment.

3. Desired output size

- Coarse crushing: Use jaw crushers, gyratory crushers and hammer crushers in primary crushing to break large materials into medium sizes.

- Medium crushing: Employ cone crushers or impact crushers in secondary crushing to further reduce material into smaller particles.

- Fine crushing: Utilize sand making machines, roll crushers, fine crushers or compound crushers in tertiary crushing to produce fine sand or powder.

4. Capacity requirements

Determine the hourly capacity needed. Choose gyratory or cone crushers for large-scale production lines, and jaw or impact crushers for medium to small-scale operations.

5. Investment and operating costs

- Initial investment: Gyratory and cone crushers have higher initial costs but lower long-term operating costs. Jaw crushers and impact crushers are more cost-effective initially.

- Operating costs: Gyratory crushers and cone crushers offer good wear resistance, while jaw plates in jaw crushers and hammers in impact crushers are susceptible to wear and are considered consumable parts.

There is a wide variety of crushers, each with unique advantages and applications in different crushing stages—whether primary, secondary, or tertiary crushing, FTM Machinery provides suitable equipment to ensure the smooth progress of your project. Contact Sales