What is beryl?

Beryl is a cyclosilicate mineral composed of beryllium aluminum cyclosilicate. Its name is derived from the Greek word "beryllos," meaning "precious blue-green gemstone." Beryl is also classified as a gemstone.

- Beryl formula: Be3Al2(SiO3)6

- Beryl color: Blue (aquamarine), yellow (heliodor), pink (morganite), colorless (goshenite), and red (red beryl).

- Crystal: It crystallizes in the hexagonal system, forming prismatic crystals.

- Hardness: 7.5-8. It is very durable and resists any scratches and abrasions.

- Beryl properties: Excellent clarity and hardness

While the most famous variety of beryl is emerald, red beryl is the rarest. The color variations are due to impurities in the beryl crystal. For example, the emerald obtains its green color from traces of chromium and vanadium.

Beryl contains a lot of beryllium, which is a very rare metal. In terms of occurrence, beryl is often found in granite pegmatites, metamorphic rocks, and hydrothermal veins, associated with tin ore and tungsten ore.

Where can you find beryl deposits?

- Emeralds are produced in Colombia and Zambia.

- Aquamarine is produced in Brazil, Russia, and Pakistan.

- High-quality morganite comes from Brazil, northern Afghanistan, and California of USA.

- Heliodor and Golden Beryl are produced in Madagascar, Russia, Minas Gerais in Brazil, and Connecticut in the United States.

- Goshenite is produced in Pakistan, China, Myanmar, and Minas Gerais in Brazil.

- The rarest beryl is found in Utah at Wah Wah Mts, Beaver Co.

Beryl mining and processing

Beryl is produced mainly as a by-product of gem mining and in small amounts for the production of beryllium.

Raw beryl stone is typically mined from pegmatite deposits, which are rich in feldspar, quartz, and mica. The mining process involves locating and extracting pegmatite veins using surface mining or underground mining.

The processing and extraction of beryl depend on the specific application or desired end product. Here is the general industrial processing method of beryl:

-

Crushing:

Crushing:

Use a jaw crusher and cone crusher to break the beryl stone into smaller particles.

-

Grinding:

Grinding:

Use a rod mill to grind it into powder (35 mesh or finer). This step can maximize the release of beryl crystals and reduce slag. The rod mill has high sealing performance and no dust spillage, which can avoid the inhalation of dust.

-

Classifying:

Classifying:

A spiral classifier is used to close the grinding circuit. It can classify the powder based on its size and quality to remove impurities, such as coarse mica flakes and glue-bound mud.

-

Beneficiation and purification:

Beneficiation and purification:

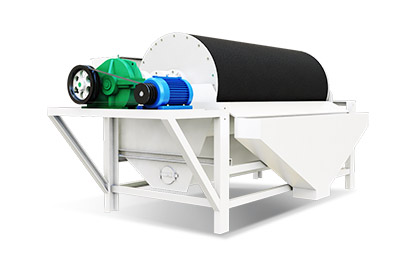

Since the specific gravity of beryl is almost the same as that of quartz and feldspar, it cannot be separated by gravity. We often use strong magnetic separators and flotation machines. First,magnetic separation can remove magnetic impurities such as garnet, tourmaline, hornblende, and biotite. Second, froth flotation is adopted. After the mica is separated, beryl and feldspar are recovered sequentially.

-

Dewatering and drying:

Dewatering and drying:

The concentrate after flotation is dewatered, filtered, and dried.

-

Finishing:

Finishing:

After beneficiation, beryl can be cut into various shapes based on its intended use. The beryl then undergoes a smoothing or polishing process and is processed into gemstones or industrial products.

Beryl uses

The most important use of beryl is as a gemstone. Its beauty, durability, and rarity make it a favored gemstone for jewelry. From emerald rings to aquamarine earrings, beryl gemstones have become coveted items in the luxury market.

- Electronics: Excellent transparency and refractive index allow for the production of optical components, such as lenses, prisms, and optical fibers. This makes it an ideal material for cameras, telescopes, microscopes, and other optical instruments.

- Telecommunications: Precise wavelength dispersion properties make beryl be used in laser technology, fiber optic communication systems, and data storage equipment.

- Aerospace and Defense: Exceptional hardness, heat resistance, and electrical insulation properties make beryl be used in lightweight aircraft parts and armor plating for military vehicles.

- Beryl is a source of beryllium. Beryllium can produce aircraft windows, spacecraft shields, nuclear reactors, insulators, and other components.

- Medical and Research: Beryl’s unique ability to fluoresce when exposed to X-rays makes it ideal for the use of X-ray detectors and lasers used in dermatology and ophthalmology.

- Energy and Power: Beryl can be processed into beryllium oxide ceramics, which are used as components in nuclear reactors and advanced nuclear fuel designs, ensuring safe and efficient energy production.

- Environmental protection: Beryl can produce high-performance catalysts to reduce automobile emission pollution.

Conclusion

Beryl is a minor ore of beryllium and one of the most important gem minerals. Its processing methods may vary depending on the mineral properties and intended use. FTM Machinery can help you test mineral properties for free and provide reliable mineral processing solutions.