Over two thousand years ago, ancient China discovered the magic of apatite, using it to create pigments that became renowned colorants for the Qin Dynasty Terracotta Warriors.

Today, apatite rock remains highly valuable, used in the production of phosphate fertilizers, gemstones, and various phosphate products essential to daily life.

Join us on an exploration journey of apatite!

Blue apatite healing properties

In 1786, German geologist Abraham Gottlob Werner named apatite from the Greek word "apate," meaning "to deceive."

Why does apatite "win this honor"? Who or what did apatite deceive?

It earned this name because of its resemblance to beryl and fluorite, often confusing mineral experts who mistook it for other gemstones.

Today, blue apatite is highly sought after and symbolizes wisdom. Wearing it is believed to promote inner peace and enhance social skills.

Some believe that due to its mineral composition being similar to human bones and tooth enamel, wearing apatite can protect bone, teeth, and cartilage health.

However, it's important to note that apatite's hardness is only 5 on the Mohs scale, compared to 7–9 for most gemstones, limiting its widespread use as a gemstone.

Apatite colors vary by location

Is apatite a rare mineral?

Many readers might be curious about this, but the answer is no. Apatite is quite abundant on Earth, with different colors found in various distribution areas.

| Types | Distribution countries |

| Blue apatite | Myanmar, Sri Lanka, Brazil |

| Blue-green apatite | Norway, South Africa |

| Purple apatite | Germany, Maine and California |

| Yellow apatite | Durango, Mexico, Spain, Canada, Brazil, China |

| Green apatite | India, Canada, Mozambique, Madagascar, Spain, Myanmar |

| Brown apatite | Canada |

| Colorless apatite | Myanmar, Italy, Germany, China |

| Blue-green apatite cat's eye | Sri Lanka, Myanmar |

| Green apatite cat eye | Brazil |

| Yellow apatite cat eye | Sri Lanka, Tanzania, China |

Apatite: phosphate mineral group

Apatite gemstone transcends its status as a mere jewel. Fundamentally, it belongs to a group of phosphate minerals.

Its chemical formula, Ca5(PO4)3(F,Cl,OH), places it predominantly within igneous, sedimentary, and metamorphic rocks, characterized by a hexagonal crystal system. Apatite exhibits a transparent to translucent glassy luster, with an average density of 3.19.

Apatite is classified into three primary types based on its chemical composition: fluoroapatite, chloroapatite, and hydroxyapatite.

Among these, fluoroapatite is the most prevalent. Fluorine aids in preventing dental caries and serves as a vital component in fluoride toothpaste.

Hydroxyapatite is a principal mineral component of human tooth enamel and bones.

Apatite's diverse uses

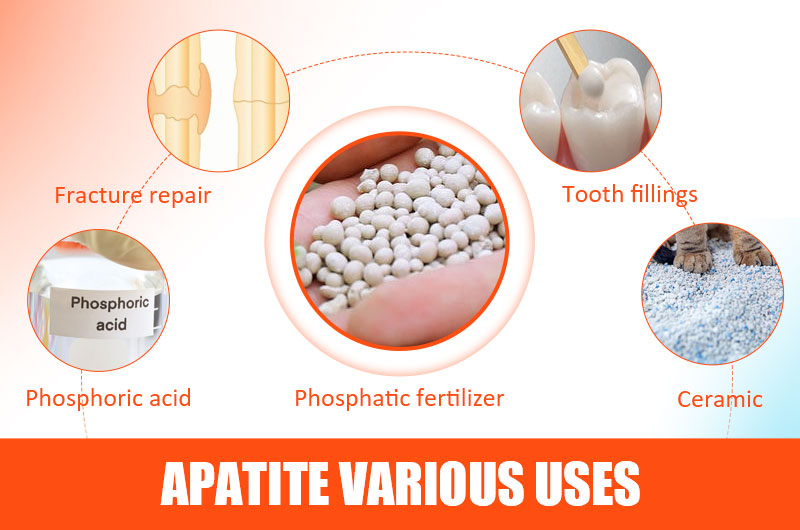

- Fertilizer: Apatite is vital for making phosphate fertilizer, benefiting crop growth, root development, and disease resistance.

- Industrial Applications: Apatite serves as a key raw material for phosphoric acid and various phosphate salts, used in food, water treatment, and pharmaceuticals.

- Ceramics: Apatite's ions improve ceramics by enhancing sintering, hardness, glaze fluidity, and product durability.

- Medical Field: Apatite is widely used in medicine for bone repair, as it integrates well with bone tissue, promoting cell growth and tissue regeneration.

- Dental Field: Apatite is used in dental applications like fillings and artificial tooth roots due to its strong bond with tooth tissue and wear resistance.

Apatite concentrate processing secrets

When apatite is used to make fertilizers or various phosphate products, it must be leached with nitric acid to extract phosphoric acid. To enhance the efficiency and cost-effectiveness of acid leaching, apatite must be processed into apatite concentrate before leaching.

How can apatite concentrate be obtained?

FTM Machinery is designed with 4 steps crushing, grinding, flotation, and drying to help you obtain apatite concentrate efficiently.

- Crushing Process

- Grinding Process

- Flotation Process

- Drying Process

Apatite, with a hardness of 5, is typically crushed using a combination of jaw and cone crushers to achieve a size of less than 20 mm during secondary crushing.

Get the latest product price

Crushed apatite particles are ground in a ball mill to achieve a particle size of 0.074–0.4 mm.

Get the latest product price

Apatite is commonly found with clay, quartz, calcite, and dolomite. Flotation separates apatite by exploiting the different surface properties of these minerals. Sodium oleate captures apatite, resulting in a phosphate concentrate with a 90% recovery rate and 50% grade.

Get the latest product price

Following apatite flotation, a Rotary Dryer is recommended for drying.

Get the latest product price

FTM Machinery customer case

The following is the production plan provided by our company for an apatite processing factory in Morocco.

| Customer Profile | An apatite processing plant in Morocco |

| Background | Moroccan apatite production accounts for more than 15% of the global total, and its reserves are abundant. The local apatite is mainly fluoroapatite, which contains higher phosphorus, but also contains more impurities such as clay quartz. |

| Customer capacity requirements | It can crush at least 60 tons of apatite per hour. Two crushers with high crushing efficiency are needed and the budget is sufficient. |

| Apatite raw ore size | About 200 mm |

| Discharge size | 0.074–0.4 mm |

FTM Machinery Solution

Considering the small feed size of the raw ore within the cone crusher's feed range (160 mm to 450 mm), we suggest employing two cone crushers.

Each crusher has a production capacity of 80 t/h, meeting the customer's production requirements. Post-crushing, the material undergoes screening via a vibrating screen, with particles smaller than 20 mm proceeding to the ball mill for wet grinding. A flotation machine is used to float the apatite concentrate, while a rotary drum dryer reduces the concentrate's moisture content.

Communication FAQ

Can you arrange exports to Morocco? What is the shipping time?

Certainly, shipping from Henan, China to Casablanca takes 37 days by sea.

Do you provide engineering services with installation guidance?

Absolutely, we will guide you throughout the process. The installation is straightforward as most machines come pre-assembled. We can provide detailed installation flowcharts, including installation precautions. If you encounter any problems during the installation, we can assist you through remote video guidance.