The construction and building materials industries are shifting towards sustainable practices, with ceramsite sand emerging as a key innovation. The blog explores its advantages, production process, and wide applications.

What is ceramsite sand?

Ceramic sand is also known as the ceramic sand. It is a porous lightweight expanded clay aggregate made by sintering clay, shale, or other similar materials at high temperatures in a rotary kiln.

There are many raw materials, so the color of the fired ceramsite sand is mostly dark red, and reddish white, and some special varieties are grayish-yellow, grayish black, grayish white, cyan, etc.

Ceramic sand is mostly fine particles less than 5 mm. The main varieties are clay ceramsite sand, shale ceramsite sand, and fly ash ceramsite sand.

Due to its excellent physical and chemical properties, ceramsite sand has become an ideal choice for various construction applications. It is increasingly used in concrete production, lightweight bricks and soil improvement.

Compared with other normal construction materials, what are the advantages of ceramsite sand?

1. Lightweight: Ceramsite sand is significantly lighter than traditional aggregates, reducing the overall weight of structures and contributing to lower transportation costs. Its lightweight nature makes it ideal for high-rise buildings and bridge construction.

2. High strength: Despite its low density, ceramsite sand boasts high compressive strength. This property ensures that structures built with ceramsite sand can withstand heavy loads, making it a reliable choice for various construction projects.

3. Thermal insulation: Ceramsite sand exhibits excellent thermal insulation properties, helping to regulate indoor temperatures and reduce energy consumption in buildings. This characteristic contributes to sustainable building practices and enhances occupant comfort.

4. Environmental benefits: The production of ceramsite sand utilizes natural materials and can be made from industrial waste, contributing to waste reduction and environmental sustainability. By replacing traditional aggregates with ceramsite sand, the construction industry can minimize its carbon footprint.

How to produce ceramsite sand?

Establishing an efficient ceramsite sand production line is crucial for meeting growing market demands. The production of ceramsite sand involves several key steps, each designed to ensure consistent quality of the end product, minimize waste, and optimize resource utilization.

The following is a detailed overview of a typical ceramsite sand production line.

1. Raw material preparation

The first step in the ceramsite sand production line is raw material preparation. The primary materials used are clay, shale, or other aggregates.

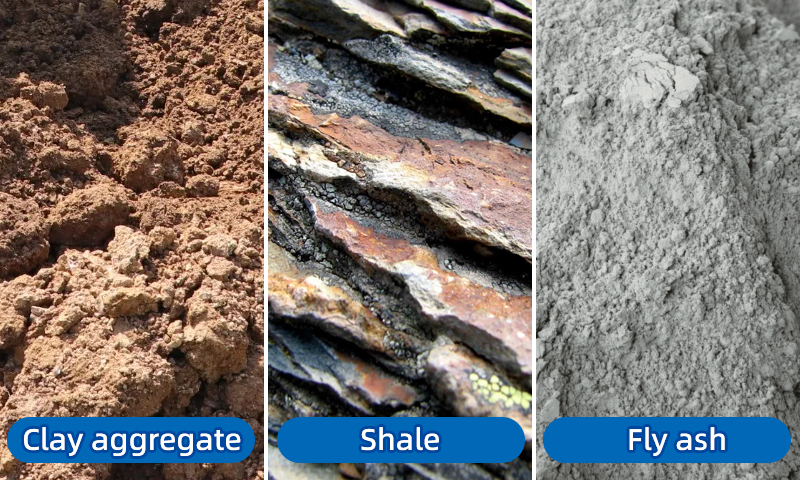

Common raw materials include:

- Clay aggregate: The primary component for ceramsite production.

- Shale: The material expands when heated to increase the strength and durability of the final product.

- Slate and fly ash: Often used as supplementary materials to improve properties.

Preparation steps are as follows:

- 1Crushing: Raw materials are crushed and ground to achieve a uniform size suitable for further processing. It is recommended to use a jaw crusher and ball mill to crush the raw materials to within 25 mm.

- 2Mixing/Blending: Mix the crushed materials (a 1:1 volume ratio is good) to form a paste to ensure the consistency of the mixture quality. This can lay the foundation for the subsequent granulation (clay aggregate balls).

2. Granulation

Once the raw materials are prepared, they undergo a granulation process. The granulation process is crucial, as it directly affects the size and density of the final ceramsite sand product.

The mixture is formed into high-strength balls of the desired size in a short time (within 15 minutes) using a granulator. The ball-forming rate can reach 93% and above. The size ranges from a few millimeters to several centimeters, depending on the application.

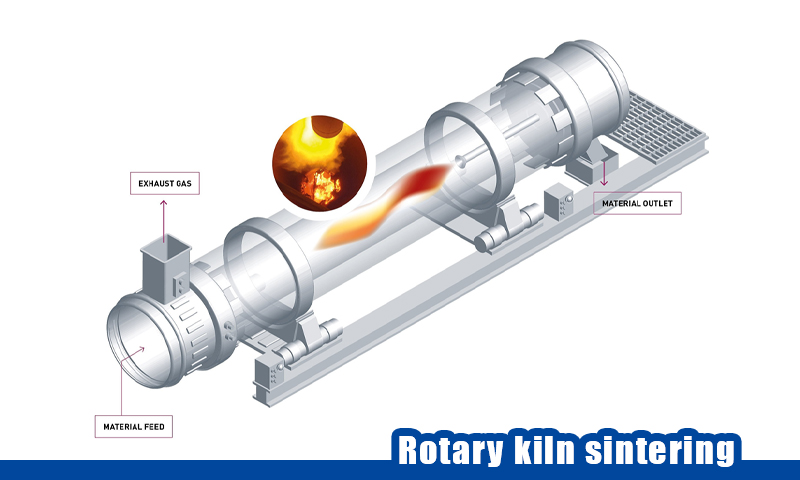

3. Rotary kiln sintering

The granulated material is then transferred to a rotary kiln. The rotary kiln is the heart of the ceramsite sand production line. This large cylindrical furnace is designed to heat the granulated material to high temperatures (usually between 1000°C and 1400°C).

Precise temperature control is essential to achieve the desired expansion and properties of ceramsite sand. The rotation of the kiln ensures even heating and prevents the material from sticking to the walls.

The sintering process causes the particles to fuse, creating a porous structure that contributes to the lightweight and insulating properties of ceramsite sand.

4. Cooling

After sintering, the ceramsite sand needs to be gradually cooled to below 200°C. A rotary cooler helps stabilize the ceramic sand, prevents it from deforming, and enhances its mechanical properties. Proper cooling also prevents thermal shock, which can lead to cracking or deformation.

Some tips for cooling you should know

- Air cooling: Utilizing ambient air to gradually lower the temperature of the ceramsite sand.

- Water cooling: In some cases, water sprays are adopted to speed up the cooling process.

5. Screening and grading

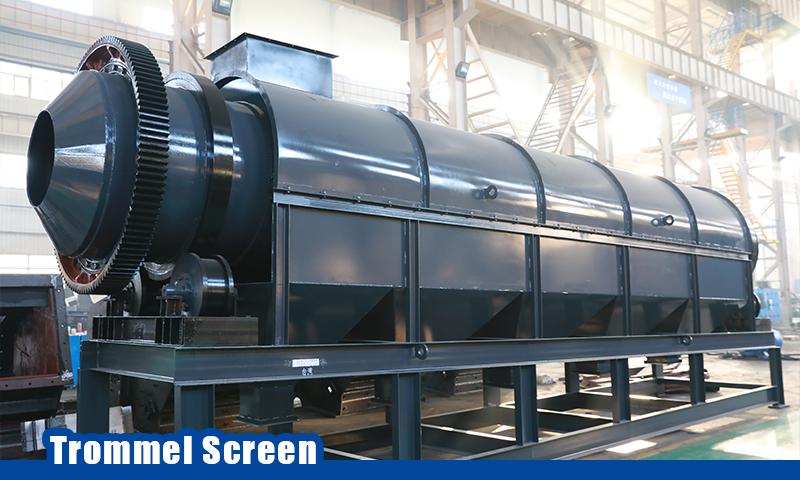

Once cooled, the ceramsite sand is screened to separate fine particles from large particles by size.

This step is important because it ensures that the final product meets the specific grading requirements of different applications.

- Quality control: Ensures uniform particle size, which is critical for applications such as lightweight concrete.

- Product diversification: Allows for the production of various grades of ceramsite sand to meet different market needs.

Unlike traditional vibrating screens, we recommend using a drum screen. This screen can screen clay materials more efficiently and prevent clogging. Generally, the output of a 2 mm screen is 19.2–56 t/h, and the output of a 30 mm screen is 280 t/h.

6. Packaging and storage

The final stage involves packaging the ceramsite sand for distribution. Proper packaging is essential to maintain product quality during transportation.

Packaging options

- Bulk Bags: Ideal for large-scale customers requiring significant quantities.

- Small Bags: Convenient for retail and smaller projects.

Wide uses of ceramsite sand

Ceramsite sand has a wide range of applications in various industries:

1. Construction

Ceramsite sand is commonly used as a lightweight aggregate in cement and concrete production, which is particularly beneficial for high-rise buildings and precast concrete elements. Its lightweight nature reduces the overall weight of structures, enabling architects to design more ambitious projects.

2. Landscaping

Due to its aesthetic appeal and lightweight properties, ceramsite sand is also popular in landscaping. It can be used as a soil amendment to improve drainage and aeration, promoting healthy plant growth.

3. Water Treatment

Ceramsite sand is increasingly used in water treatment applications, particularly in filtration systems. Its porous structure allows for efficient filtration, helping to remove impurities from water.

4. Agriculture

In agriculture, ceramsite sand can enhance soil structure, improve drainage, and increase aeration. Its lightweight nature makes it suitable for container gardening and hydroponics.

Conclusion

The ceramsite sand production line represents a significant advancement in the field of construction materials. By producing lightweight, high-strength aggregates, this innovative approach not only meets the needs of modern construction, but also promotes sustainable practices.

If you are considering ceramsite sand for your next project, or are interested in setting up a production line, don’t hesitate to reach out to industry experts for tailor-made solutions and insights. Embrace the future of construction with ceramsite sand!