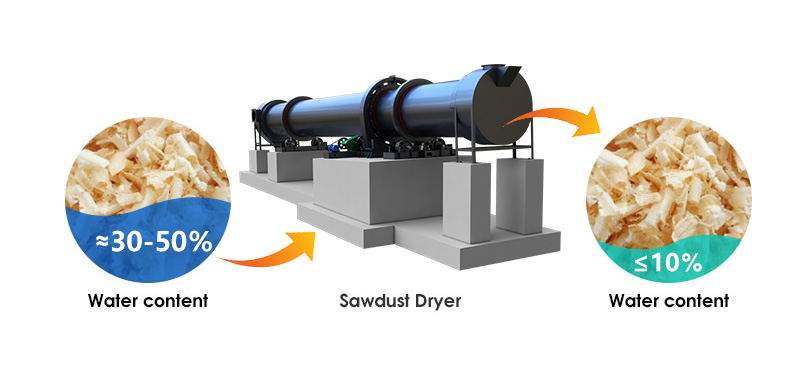

If you're in the biomass energy or organic recycling industry, you know sawdust is a key raw material for biomass pellets. However, high moisture (30%–50% ) can cut heating value by up to 60%, leading to inefficient combustion.

Drying sawdust to ≤10% moisture boots heating value by 40%–60%, enabling cleaner, more efficient burning.

Traditional air drying is slow, weather-dependent, and unsuitable for large-scale production. That's why FTM Machinery's high-efficiency sawdust dryer delivers fast, uniform, and energy-efficient drying, maximizing resource use and profitability.

What is a sawdust dryer?

A sawdust dryer (biomass dryer) utilizes advanced hot air circulation technology to process biomass materials with a moisture content of up to 65%, reducing it to 8%–12% in a single drying cycle.

It is ideal for drying various biomass materials, including straw, rice husk, wood chips, forage, corn cobs, distiller's grains, sweet potato residue, bagasse, fruit pomace, bamboo shavings, and paper scraps. The drying machine is widely used in agriculture, wood processing plants, biomass fuel production, and paper manufacturing.

- Wood processing plants: Improve sawdust utilization and reduce waste.

- Biomass energy: Produce high-quality biomass fuel.

- Paper industry: Dry pulp for efficient paper production.

- Animal feed industry: Dry wood-based feed to enhance nutrition.

To meet different drying needs, FTM Machinery offers customizable sawdust dryers in various sizes and configurations based on specific material needs. Get a Free Quote!

| Spec./m(Dia.×Length) | Shell Cubage(m³) | Capacity(t/h) | Highest Inlet Air Temperature(℃) |

| Φ1.2×8.0 | 9.0 | 1.9–2.4 | 700–800 |

| Φ2.2×12 | 45.6 | 9.7–12.2 | 700–800 |

| Φ2.4×20 | 90.4 | 19.3–24.1 | 700–800 |

| Φ3.0×20 | 141.3 | 30.1–37.7 | 700–800 |

| Φ3.6×28 | 285 | 60.8–76.0 | 700–800 |

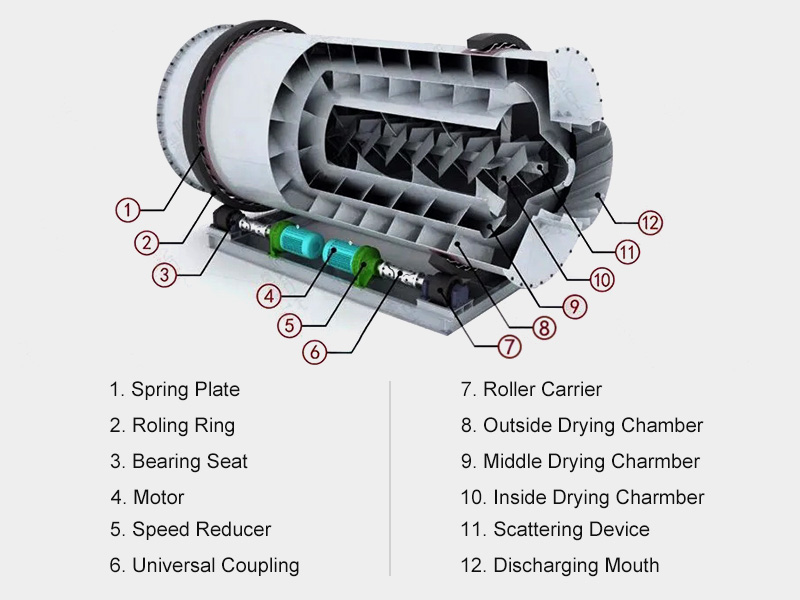

Key components of a sawdust rotary dryer

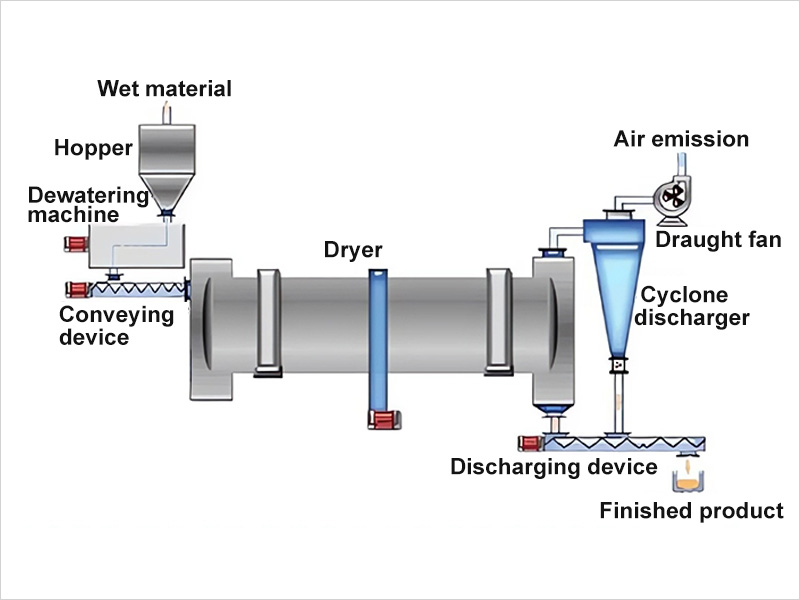

A sawdust rotary dryer consists of five main components: feeding system, rotary drum, hot air system, drive mechanism, and discharge system.

1. Feeding system

Ensures uniform feeding of wet sawdust, preventing clogging and uneven drying.

Typically consists of a belt conveyor or screw feeder.

2. Rotary drum

The core component, made of high-temperature and corrosion-resistant materials (e.g., stainless steel).

Inside, lifting plates disperse the material, allowing full contact with hot air for efficient drying.

3. Hot air system

Includes a burner, hot air ducts, and a fan, supporting various fuels like biomass, natural gas, and diesel.

The hot air is forced into the drum by a fan, ensuring continuous circulation for consistent drying.

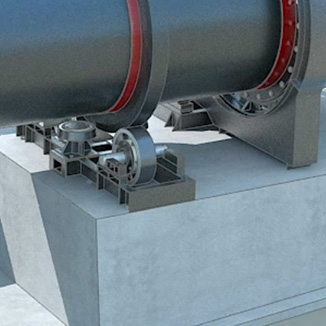

4. Drive mechanism

Comprising a motor, reducer, and drum support structure, it drives the drum rotation, ensuring even heat distribution across the material.

5. Discharge system

Uses a screw conveyor or vibrating conveyor to transport dried sawdust for storage or further processing.

How does a sawdust dryer work?

- 1 Wet sawdust enters the rotary drum dryer.

- 2 Lifting plates inside the drum toss the sawdust into the hot airflow for even heating.

- 3 As the drum rotates, sawdust moves toward the outlet while moisture evaporates.

- 4 Multi-stage dust removal and heat recovery ensure environmental compliance and energy efficiency.

- 5 The result is uniformly dried sawdust, ready for biomass fuel, papermaking, or other uses.

Why choose FTM Machinery sawdust dryers?

FTM Machinery, a leading sawdust dryer manufacturer, offers high-quality sawdust dryers for sale at competitive prices. Below are the key advantages of our dryers:

- High efficiency & energy saving: Advanced hot air circulation boosts heat efficiency by 40%, saving 35% more energy than traditional dryers.

- Fast drying: High-temperature airflow and multi-layer drying ensure consistent results, even for high-moisture materials like fresh wood chips or wet straw.

- Durable construction: The rotary drum features high-quality stainless steel and heat-resistant materials for hardness, corrosion, and wear resistance.

- Optimized insulation: Double-layer insulation minimizes heat loss, ensuring high efficiency even in cold climates.

- Smart control: PLC automatic control system monitors and adjusts temperature, humidity, and airflow in real time.

- Flexible fuel options: Compatible with coal, biomass, natural gas, or diesel, offering cost-effective operation.

- Multiple fuel options: Supports coal, oil, gas, etc. Low fuel consumption, no air leakage, complete combustion, and drying costs are only one-third of similar products.

- Customizable solutions: From 1.9 t/h mini drying machines to 76 t/h industrial dryers, tailored to meet various production needs.

FTM Machinery sawdust dryer for sale:Get the Latest Price

Customer case: sawdust drying solution for a Brazilian wood processing plant

A Brazilian wood plant faced a challenge in drying 50% moisture sawdust efficiently to convert waste into valuable biomass fuel.

FTM Machinery's sawdust drying system provided the perfect solution.

| Initial moisture | 55% |

| Final moisture | 8% |

| Capacity | 30 TPH |

| Operating hours/day | 20 hours |

| Heat source | Natural gas |

Customer feedback:

"After six months of operation, the dried sawdust maintains a stable 8% moisture level. The fully automated system runs smoothly with minimal supervision, and FTM Machinery's support team ensures everything works perfectly."

Frequently asked questions about sawdust rotary dryers

1. How to control drying temperature?

- a. Segmented heating: Start with low-temperature preheating, gradually increasing to the optimal drying level.

- b. Avoid overheating: Prevent carbonization or burning that affects product quality.

- c. Real-time monitoring: Temperature sensors keep fluctuations within ±5°C.

2. How to maintain a sawdust dryer (biomass dryer)?

- a. Regularly lubricate transmission parts and bearings.

- b. Clean hot air ducts and filters to prevent clogging.

- c. Check drum wear and replace worn-out components if needed.

3. How to operate a sawdust dryer?

- a. Ensure proper installation, leak-free operation.

- b. Preheat the hot air furnace to 150°C.

- c. Feed wet sawdust evenly to avoid overloading.

- d. Adjust heat and airflow based on material moisture.

- e. Secure inspection covers to prevent air leakage.

- f. Use a bag dust collector to reduce emissions.

4. What are the shutdown steps for the sawdust dryer?

- a. Stop feeding: Turn off the feeding system and ensure all material is discharged from the drum.

- b. Cooling process: Gradually reduce the hot air temperature to avoid sudden cooling.

- c. Turn off the heat source: Shut down the burner or heating system once the temperature reaches a safe level.

- d. Stop the transmission: Turn off the motor to stop drum rotation.

- e. Clean the machine: Remove any remaining material and inspect the system.