Kyanite, this beautiful blue gemstone, has long been regarded as a symbol of wealth, power, and status since ancient times.

During the ancient Egyptian period, pharaohs fashioned it into talismans and jewelry, while in medieval Europe, it adorned crowns, royal jewels, and church decorations.

Additionally, its ocean-like color has led people to attribute healing properties to it, such as purifying the soul, relieving pain, and alleviating stress.

Today, mined kyanite is primarily used in the steel industry for refractory materials. Additionally, it finds application in abrasives, ceramics, casting, and as gemstones for crafting jewelry pieces such as necklaces, earrings, bracelets, as well as ornamental stones and carved artworks.

What is kyanite?

Kyanite is an aluminum silicate mineral commonly found in regional metamorphic rocks, gneisses, crystalline granites, and quartz veins, often occurring alongside minerals such as quartz, mica, sillimanite, feldspar, and garnet.

Do you know? Kyanite exhibits varying hardness in different directions!

When measured along the crystal's long axis, its hardness is approximately 4.5 to 5, whereas perpendicular to the long axis, the hardness increases to 6.5 to 7. Therefore, it is classified as a mineral with "anisotropic hardness."

Properties of kyanite:

- Chemical formula: Al2SiO5

- Crystal system: Triclinic

- Color: Blue (most common), cyan, green, gray, etc.

- Tenacity: Brittle

- Luster: Vitreous to pearly

- Streak: White

- Transparency: Transparent to translucent

- Specific gravity: 3.53–3.65

This unique mineral resource is distributed across various regions globally, including Brazil, India, Kenya, Myanmar, Austria, Switzerland, Zimbabwe, and the United States.

How to process kyanite?

Kyanite, as an important industrial raw material, is typically supplied to industries such as steel, ceramics, and glass in the form of powder or granules.

Achieving high-grade kyanite concentrates requires a crucial beneficiation process. Kyanite beneficiation often involves gravity separation and flotation as the primary methods, with magnetic separation used for impurity removal.

Below are the experimental results conducted by FTM Machinery specifically for complex garnet-kyanite-biotite-quartz schist:

The main minerals in the ore include kyanite, biotite, muscovite, garnet, and quartz, with minor minerals such as plagioclase, chlorite, and pyrrhotite.

The process flow includes the following:

- Ore crushing

- Dry magnetic separation for tailings disposal

- Grinding

- Spiral chute for tailings disposal

- Re-grinding

- Kyanite flotation

- Magnetic separation for iron removal

-

Kyanite Crushing

Kyanite Crushing

The jaw crusher and impact crusher are indispensable in this stage. The kyanite ore is sequentially crushed to 4 mm. Vibrating screens sieve out large ore particles and return them for further crushing.

-

Dry Magnetic Separation for Tailings Disposal

Dry Magnetic Separation for Tailings Disposal

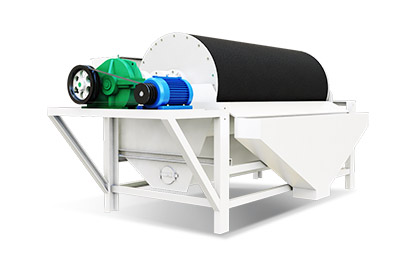

The magnetic separator is set with a magnetic field intensity of 796 kA/m and a drum rotation speed of 30 r/min for dry magnetic separation of the 4mm ore. After 4 rounds of magnetic separation, most of the magnetic minerals are discarded.

At this stage, the enriched kyanite grade can reach 13.77%, with a recovery rate of 90.58%.

-

Spiral Chute for Tailings Disposal

Spiral Chute for Tailings Disposal

Before gravity beneficiation, the raw ore needs to be ground. This process is completed in a ball mill. When the grinding fineness of kyanite reaches -0.15 mm with 47% passing, the spiral chute achieves the best separation effect.

At this point, the kyanite grade reaches 18.47% with a recovery rate of 95.20%, while the Al2O3 grade and recovery rate also reach 17.34% and 61.14%, respectively.

-

Kyanite Flotation

Kyanite Flotation

Before flotation, further grinding of the concentrate obtained in the previous stage is required until the grinding fineness reaches -0.15 mm with 75% passing.

Subsequently, 4 stages of roughing and 2 stages of scavenging are conducted in the flotation machine, maintaining a flotation concentration of 30%. During this process, the grade and recovery rate of the concentrate are significantly improved.

Finally, we obtain a kyanite concentrate grade of 95.26% with a recovery rate of 75.53%. The Al2O3 grade and recovery rate are 58.74% and 20.97%, respectively.

-

Kyanite Magnetic Separation for Iron Removal

Kyanite Magnetic Separation for Iron Removal

Nevertheless, the Fe2O3 content in the concentrate is still relatively high and must be removed by magnetic separation. When the magnetic field intensity is 478 kA/m, the Fe2O3 content in the kyanite concentrate decreases to less than 1%.

Lastly, the kyanite concentrate undergoes drying process, completed either through natural air drying or using a rotary drum dryer, to meet industrial standards.

FTM Machinery Recommends:

If your ore mainly consists of finely disseminated kyanite, flotation would be an efficient choice. For ores containing a mixture of coarse and finely disseminated kyanite, a combined gravity-floatation process would be more suitable.

It's worth mentioning kyanite, andalusite, and sillimanite share the same chemical composition. When subjected to high-temperature calcination, they decompose and transform into mullite.

Mullite exhibits stable volume, low thermal expansion coefficient, excellent electrical insulation properties, and thermal load-bearing capabilities, making it suitable for advanced refractory materials, ceramics, heating elements, brake pads, kiln furniture, investment casting flours, and stuccos, among others.