What is a clay dryer?

Clay is a natural mineral widely used in industries such as ceramics, brick and tile production, refractory materials, paper manufacturing, and construction.

Clay extracted from the earth typically contains 30%–50% moisture, which can affect subsequent processes like molding and firing.

A clay dryer is an industrial rotary drying equipment designed specifically for drying materials such as clay, kaolin, and bentonite. It uses direct or indirect heating methods to remove moisture, preparing the clay for optimal processing.

Which types of clay are suitable for a clay dryer?

Clay dryers are suitable for drying a variety of clay types, including kaolin, bentonite clay, red clay, refractory clay, earthenware clay, ball clay, gypsum clay, and bleaching clay.

Different types of clay have varying moisture content when extracted. To ensure efficient and high-quality subsequent processing, a clay dryer is often used to reduce the moisture content to an ideal level.

Common moisture content in clay during extraction and after drying:

| Clay types | Moisture before drying | Moisture after drying |

| Kaolin | 20%–40% | ≤5% |

| Bentonite | 30%–45% | 8%–12% |

| Refractory clay | 25%–35% | 5%–8% |

| Ball clay | 20%–30% | 5%–8% |

| Earthenware clay | 25%–35% | 5%–10% |

1. Refractory clay

Refractory clay is a type of clay and bauxite used for refractory materials with a fire resistance above 1580°C.

It maintains stability at high temperatures, is slag-resistant, shock-resistant, and has good mechanical strength, making it very durable after firing.

Metallurgical industry: Used to produce refractory materials, including fire bricks, fire clay, and coatings, accounting for about 70% of total refractory material consumption.

Construction industry: After calcination, high-alumina clay mixed with limestone makes rapid-hardening, corrosion-resistant, heat-resistant alumina cement.

Grinding industry: Melted and processed into abrasives, which make up about 2/3 of all abrasive products.

Other industries: Used in ceramics, oil well additives, fertilizer aids, and road materials due to its slip-resistant and wear-resistant properties.

2. Kaolin (China clay)

Kaolin is a white clay made up of a mixture of aluminum silicate minerals, including kaolinite, halloysite, small amounts of montmorillonite, and mica. It has high-temperature resistance and good adsorption properties.

Paper industry: Improves paper brightness and smoothness.

Ceramics: Key raw material for porcelain.

Rubber industry: Used as a filler to improve rubber strength and acid resistance; also an important raw material for refractory equipment.

3. Bentonite

Bentonite is a mineral rich in montmorillonite with strong water absorption and expansion properties, able to absorb up to five times its weight in water and form a gel.

Drilling: Used as a mud additive to stabilize drilling fluids.

Casting: Used to make molding sand, improving casting accuracy.

Cat litter: Due to its high absorption and clumping ability, it is an effective adsorbent material.

Wastewater treatment: Adsorbs heavy metal ions and organic pollutants, improving water quality.

4. Ball clay

Ball clay is a fine-grained aluminum silicate sedimentary mineral that is easily dispersed in water and has strong plasticity and adhesion. After firing, it becomes soft, highly adhesive, and is typically white, yellow, or red in color.

Ball clay is often mixed with kaolin and is an important binding clay in the ceramics industry.

Ceramics: Enhances the strength and durability of ceramic products.

Refractory materials: Used to produce dense clay bricks and high-quality aluminum bricks.

5. Earthenware clay

Earthenware clay primarily consists of kaolinite, water mica, montmorillonite, quartz, and feldspar, with uneven particle sizes and often containing sand, silt, and clay.

It has good water absorption and plasticity, with a firing temperature below 1250°C, making it a low-temperature sintering clay.

Construction materials: Used for manufacturing exterior wall tiles and floor tiles.

Ceramics: Used in the production of pottery, earthenware products, and decorative ceramics.

Why choose FTM Machinery clay dryer?

FTM Machinery is a leading manufacturer of high-quality clay rotary dryers, offering customized drying solutions and comprehensive parts and service support. Contact us

Our clay dryers offer the following benefits:

- Fast drying: Advanced hot air technology and optimized structure increase drying speed by 60% compared to traditional methods.

- Large drying area: High airflow speed ensures the entire surface is an effective drying zone, making heat transfer faster and more efficient.

- Low adhesion: Multi-combination lifting plate enhances heat transfer while reducing material sticking to the drum walls.

- Energy efficient: Heat recovery system cuts fuel consumption by 30%-40%, lowering costs.

- Durable & stable: Wear-resistant drum materials extend service life to 10+ years, reducing maintenance.

- Easy operation: PLC automation control system with one-touch start, reducing labor costs.

- Fuel versatility: Supports natural gas, coal, biomass, diesel, and more, meeting different needs.

- Eco-friendly: Fully sealed system with a complete dust removal system to prevent dust leakage and optimize the working environment.

Here are the key technical specifications of our clay dryer:

| Spec./m(Dia.×Length) | Shell Cubage(m³) | Capacity(t/h) | Highest Inlet Air Temperature(℃) |

| Φ1.2×8.0 | 9.0 | 1.9–2.4 | 700–800 |

| Φ2.2×12 | 45.6 | 9.7–12.2 | 700–800 |

| Φ2.4×20 | 90.4 | 19.3–24.1 | 700–800 |

| Φ3.0×20 | 141.3 | 30.1–37.7 | 700–800 |

| Φ3.6×28 | 285 | 60.8–76.0 | 700–800 |

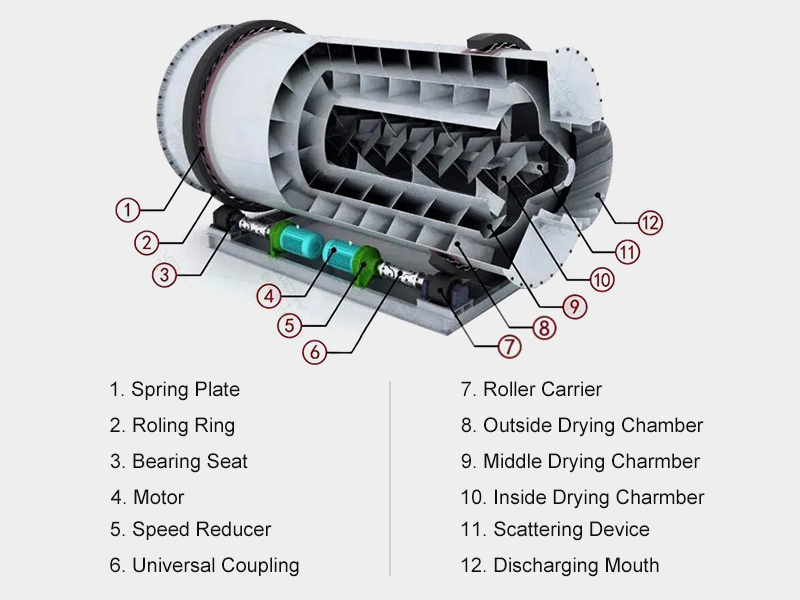

Core structure of a clay dryer

The core components of the clay dryer include the drum, lifting plates, hot air system, drive system, and control system. These parts work together to achieve efficient drying.

1. Rotary drum

Made of wear-resistant and high-temperature-resistant materials, it is installed at a slight incline and rotates at a speed of 2-6 RPM.

Driven by gears, it facilitates material tumbling for efficient drying. Both direct and indirect heating methods can be used.

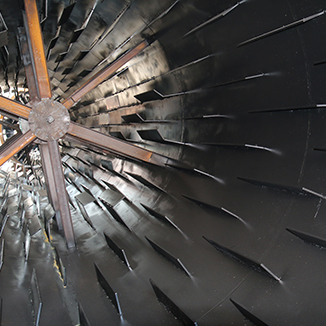

2. Lifting plates

Installed on the drum's inner wall, they lift and drop the material, ensuring full contact with the hot air to enhance drying efficiency.

The design and angle of the plates directly affect the drying performance.

3. Hot air system

Provides the necessary heat energy for drying. The heat source can come from a combustion furnace or other heating equipment.

It supports various fuels, including coal, biomass, natural gas, and diesel, making it adaptable to different needs.

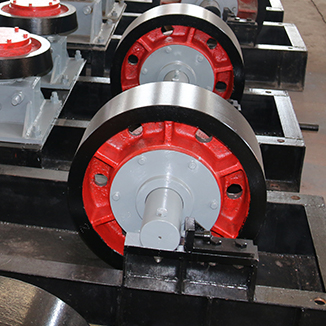

4. Drive system

Drives the rotation of the drum, usually consisting of a motor, reducer, and gears. The motor powers the gear through the reducer, which turns the drum.

5. Control system

Monitors and adjusts operating parameters such as temperature, humidity, and rotation speed.

Modern clay dryers typically feature a PLC control system for automated operation.

How does the clay dryer work?

FTM Machinery's clay dryer features a rotary drum design, where high-temperature hot air and the rotating drum work together to dry the material.

This video demonstrates the working principle of the clay dryer:

- 1 Feeding: Wet clay is transported into the dryer through a conveyor system.

- 2 Hot air drying: High-temperature air generated by the furnace contacts the clay, evaporating the moisture.

- 3 Drum tumble: Lifting plates inside the drum continuously flip the material, ensuring even heat exposure.

- 4 Moisture evaporation: Moisture is carried away by the airflow, and the dried clay moves toward the discharge end.

- 5 Finished product: Dried clay is transported via a belt conveyor or screw conveyor for the next production stage.

FTM Machinery clay dryer customer case

1. Indonesia 5TPH kaolin dryer

A factory in Indonesia needed to dry 80 tons of wet kaolin (45% moisture) daily but faced high energy consumption, uneven drying, and increased production costs with their existing equipment.

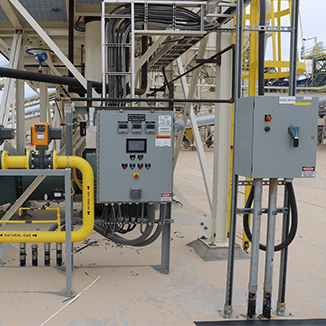

FTM Machinery provided a φ2.2×12 rotary clay dryer, equipped with a natural gas combustion system and intelligent control system, optimizing the drying process.

Project results:

- Drying time reduced by 50%, boosting efficiency.

- Fuel consumption cut by 35%, saving $8,000+ annually.

- Product quality improved, enhancing competitiveness.

Michael S., Factory Manager:

"FTM Machinery's clay dryer transformed our production line. The automation and energy-efficient design have revitalized our factory!"

2. USA 30TPH ball clay dryer

A mining company in the USA needed an efficient and reliable dryer to handle growing ball clay processing demands, reduce energy use, and meet environmental standards.

We recommended a φ2.6×24 rotary dryer specifically designed for ball clay.

Project results:

- Increased capacity: Over 200 tons dried daily, boosting efficiency.

- Reduced energy use: 15% less energy consumption, lowering costs.

- Environmental compliance: Advanced exhaust system reduces dust emissions, meeting regulations.

Mining Company Representative:

"The dryer runs smoothly, delivering consistent quality and meeting our sustainability standards— a great investment."

Frequently asked questions about clay rotary dryers

1. What is the difference between sand and clay?

- Sand particles are larger, mainly composed of silicate minerals like quartz, and have a rough texture with low water absorption. Sandy soil, which has a high sand content, provides little to no nutrients for plants.

- In contrast, clay particles are very fine, sticky, and water-resistant. Clay contains elements like aluminum, magnesium, iron, sodium, potassium, and calcium, which provide some nutrients for plants.

2. What to do if clay has high moisture content and is hard to dry?

- If the clay has high moisture, extend the drying time by increasing the length-to-diameter ratio of the dryer, allowing the clay to stay in the system longer.

- Additionally, optimize the lifting system with a combination lifting plate to improve heat and material contact, speeding up moisture evaporation.

3. How to reduce dust emissions from a clay dryer?

- Maintain a negative pressure environment to ensure high-temperature gases quickly enter the dryer and effectively exchange heat with the clay, minimizing dust escape.

- Also, reduce exhaust temperature to maintain drying efficiency and lower the release of unburned particles.

- We recommend using cyclone or baghouse dust collectors for efficient dust removal.

4. How much does clay shrink after drying?

- The shrinkage rate varies by clay type, depending on mineral composition and particle size.

- Kaolin: Shrinkage rate of 3%-10% (higher shrinkage with more illite content).

- Bentonite: Shrinkage rate of 12%-23%, with finer particles leading to higher shrinkage.