If you are not engaged in manufacturing, it is easy to underestimate the key role of industrial dryers. In the construction market, the industrial rotary dryer is an important investment project.

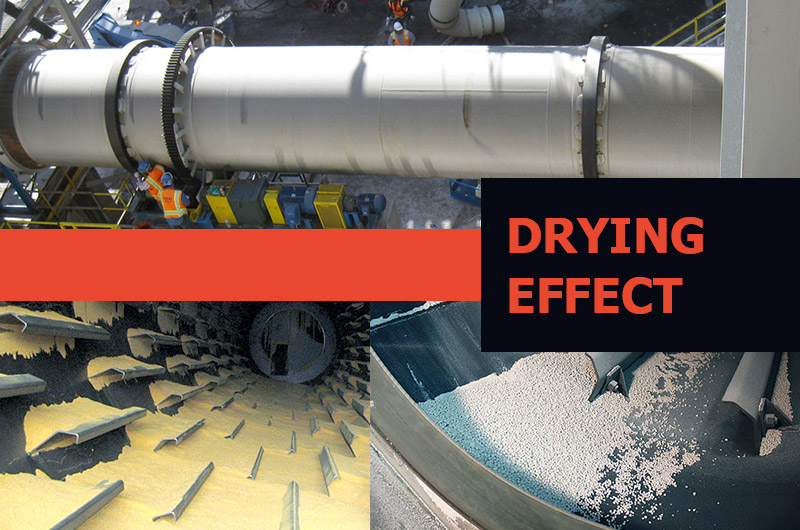

The industrial rotary dryer is also called a "drum dryer" because it uses a drying drum to dry materials containing moisture. The dried materials are used in the fields of building materials, chemicals, mineral processing, metallurgy, printing, and fertilizers.

Practical rotary dryer types

FTM Machinery has over 40 years of drum drying experience in sand drying, agricultural waste, municipal sludge, and mineral drying. The best-selling rotary drying equipment on the market is the rotary dryer with a drying drum.

The rotary dryer working principle is as follows: The material is fed into one end of a rotating drum. It is lifted by internal fins as the drum rotates and then poured down by hot steam. This removes moisture and produces a dry product.

Rotary dryer

According to the different drying needs of users, the rotary dryer machine can be classified according to heat transfer mode and structure.

1. Dryers by heat transfer mode

- Direct heat transfer dryer: Hot combustion gas is in direct contact with the material in the drum, which is more applicable. Direct dryers are by far the most effective and are the preferred choice for most drying plants.

- Indirect heat transfer dryer: An external heat source is used to heat the drum, which then indirectly transfers heat to wet materials. This type is ideal for heat-sensitive materials or processes that require isolation from combustion gases.

2. Dryers by structure

- Single drum dryer: A slightly inclined heavy cylinder is used as the drying body. It has a simple structure, strong adaptability, durability, low energy cost, and thus less investment.

- Double drum dryer: Composed of two cylinders with different diameters. The thermal efficiency is higher than that of the single-drum dryer, and the energy-saving effect is more significant.

- Three drum dryer: Composed of three coaxial horizontal cylinders with a compact footprint, 50% smaller than a single-cylinder dryer. The drying output is high, with three-layer insulation. However, the structure is complex and the maintenance is difficult.

Of course, you can also determine the type of drum dryer according to the material to be dried and its uses. This is much faster and more targeted!

- Sand dryer: Used for river sand, sea sand, yellow sand, artificial sand (silica sand, quartz sand, dolomite sand, etc.), molding sand, fracturing sand, etc.

- Coal dryer: Used for coal, coal slime, anthracite, lignite, coke, petroleum coke, activated carbon, carbon black particles, charcoal, etc.

- Mineral dryer: Used for various minerals and stones, such as gold ore, iron ore, copper ore, gypsum, limestone, phosphate, aggregate, etc.

- Clay dryer: Used for kaolin clay, bentonite, bauxite, diatomite, active clay, etc.

- Biomass dryer: Used for sawdust, wood chips, wood shavings, bagasse, corn cobs, and all kinds of straw.

- Slag dryer: Used for cement, aggregate, sludge, fertilizer, slag, alkali slag, acid slag, and traditional Chinese medicine slag in construction, chemical, and industrial industries.

How to choose an ideal rotary dryer?

There are so many specifications and types of rotary dryers, how can we choose the right one?

Six factors should be considered:

1. Materials to be dried

Understand the specific parameters of the material to be dried, such as size, density, heat sensitivity, fluidity, corrosiveness, flammability, etc.

Among them, the size and density of the material determine the size and capacity of the dryer to be purchased.

2. Moisture content

Moisture content affects the drying rate. Check materials for excess water or impurities to ensure fast drying. Final moisture can reach below 0.5–1%. Test the dryer in advance to assess efficiency and size. Adjust the dryer size if the final moisture deviates from the target.

Moisture requirements for common drying materials: Limestone (<1%), clay raw material (<1.5%), iron raw material (<2%), slag (<2%), coal (1–2%).

3. Output requirements

Customers need to combine production needs and final output to ensure that the capacity is slightly higher than the demand.

Small dryer is prone to clogging, and large dryer will waste energy and fuel when running. Our dryers range from 1.9–76 tons/hour, with three-drum models reaching a large output of 20–30 tons/hour.

4. Energy conditions

When choosing a dryer, you need to consider the local energy situation and make full use of local resources.

For example, in areas with more coal, coal is used as the fuel for the dryer; in areas with strict environmental protection policies, fuel or natural gas is used as the heat source.

5. Construction site

Depending on the location of equipment installation, the requirements for rotary dryer models and installation are also different.

Users should assess the site environment and scale, and coordinate with the size of the rotary drying equipment. Otherwise, there may be site residue or the dryer may be too large to be installed.

6. Reliable drum dryer manufacturer

Experienced rotary dryer manufacturers offer effective drum drying solutions tailored to production needs and materials.

They provide advanced R&D, continuously improving industrial drum dryer performance for low-carbon production while ensuring strong after-sales support.

Choose FTM Machinery rotary dryers for your drying plant

FTM Machinery offers integrated production, sales, and after-sales support, including expert installation, usage, and maintenance guidance.

Why Choose Us?

- High drying efficiency: Fast drying speed with excellent drying effect

- Durable parts: Alloy components last 4x longer than ordinary steel plates, with a high-temperature-resistant cylinder for fewer failures

- Energy saving: Optimized air ducts maximize heat utilization rate and minimize fuel consumption

- Easy operation: Automated system with simple temperature control

- Cost-effective: 3–10% lower prices than other dryer manufacturers and lower maintenance costs

Finally, FTM Machinery advises mastering proper equipment operation to prevent damage and ensure optimal drying. Follow these six steps for the best drying effect.

1. Startup preparation: Preheat the rotary dryer machine gradually to prevent intense burning. deformation. Rotate the drum for even heating.

2. Material moisture control: Those with high moisture should be dewatered before drying. This improves drum drying efficiency and reduces dryer wear.

3. Control feed amount: Avoid overloading to ensure proper drying and prevent operational issues.

4. Ensure stable feeding: The dryer relies on full contact between materials and the heat carrier. Maintain a consistent feed of materials and fuels to ensure efficient heat exchange and drying. Avoiding sudden changes in feed ratio.

5. Drying time control: Adjust drying time for the best drying effect. Too long drying time causes over drying, while too short drying time leaves materials insufficiently dried.

6. Shut down the engine: Reduce the fuel supply to the hot air furnace, stop feeding materials, and allow the drum to fully dry and discharge before turning off the motor.

If you have chosen the best rotary drying equipment for your drying plant, Contact Our Engineers for the latest quote—we are online 24/7!